- export5@runpingpp.com

- 24 Hours Online

Industry News

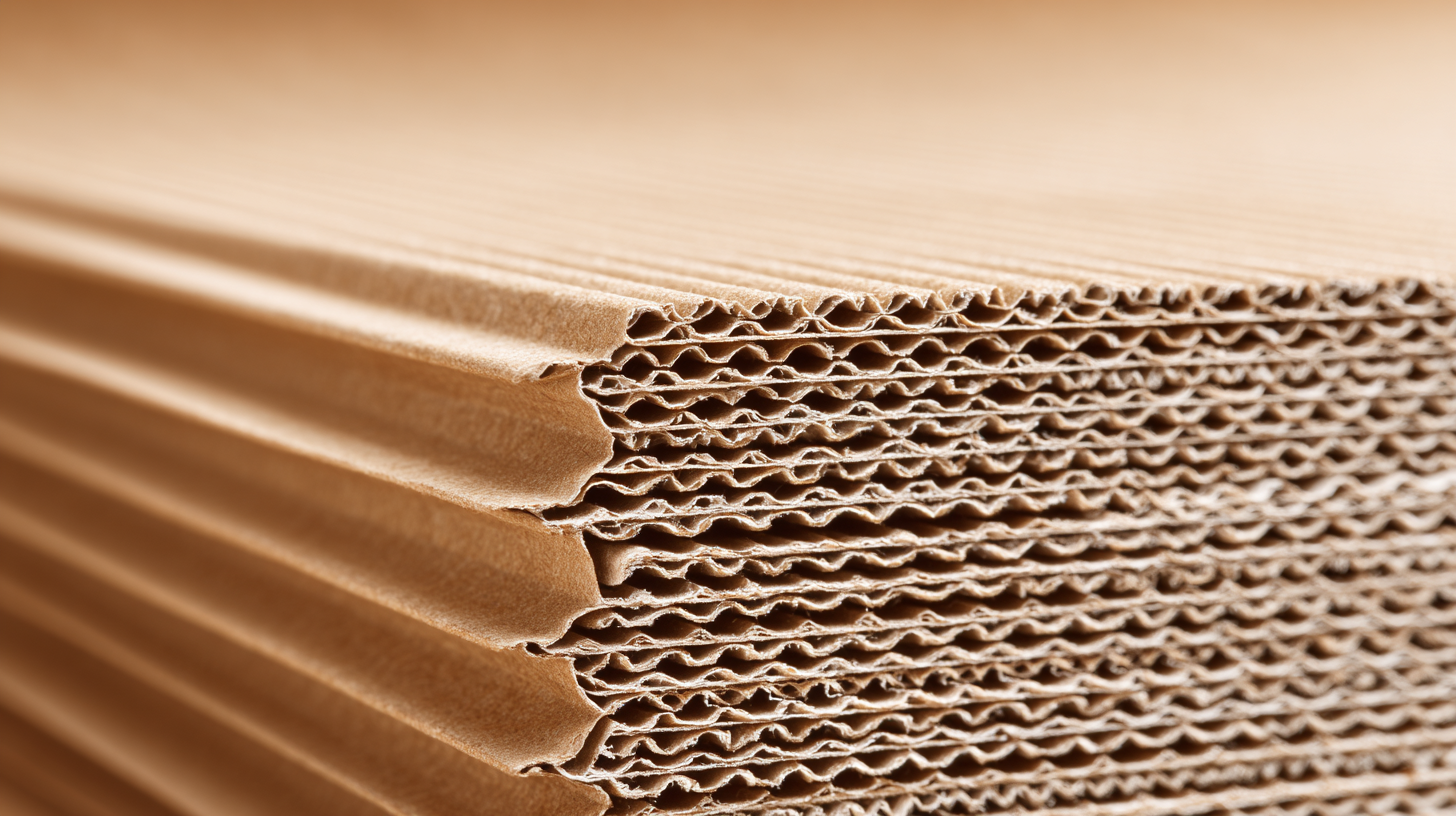

Understanding the Benefits of Pp Corrugated Board: A Sustainable Choice for Packaging Solutions

In recent years, the packaging industry has increasingly turned towards sustainable solutions, with Pp Corrugated Board emerging as a frontrunner. According to a report by Smithers Pira, the global market for sustainable packaging is projected to reach $475 billion by 2028, reflecting a significant shift in consumer preferences towards eco-friendly options. Pp Corrugated Board, known for its lightweight, durable, and recyclable properties, plays a crucial role in this transition. With a reduction of up to 60% in weight compared to traditional materials, it minimizes transportation costs and carbon emissions, aligning with the industry's sustainability goals. Moreover, a study by the Paper and Plastic Product Recycling Association indicates that using Pp Corrugated Board can increase recycling rates by 30%, further enhancing its environmental credentials. As businesses strive to meet both consumer demands for sustainability and regulatory pressures, adopting Pp Corrugated Board in packaging solutions represents a strategic and responsible choice.

How to Identify the Key Advantages of PP Corrugated Board in Packaging

PP corrugated board is gaining recognition in the packaging industry for its outstanding advantages, making it a sustainable choice for diverse packaging needs. One of the key benefits of PP corrugated board is its durability; it is resistant to moisture, chemicals, and physical stress, ensuring that products remain protected during transit. This resilience translates to fewer damages and losses, which not only optimizes the supply chain but also reduces waste. Additionally, PP corrugated board is lightweight, which contributes to lower shipping costs and decreased carbon footprints, aligning with the growing demand for sustainable practices.

PP corrugated board is gaining recognition in the packaging industry for its outstanding advantages, making it a sustainable choice for diverse packaging needs. One of the key benefits of PP corrugated board is its durability; it is resistant to moisture, chemicals, and physical stress, ensuring that products remain protected during transit. This resilience translates to fewer damages and losses, which not only optimizes the supply chain but also reduces waste. Additionally, PP corrugated board is lightweight, which contributes to lower shipping costs and decreased carbon footprints, aligning with the growing demand for sustainable practices.

Another significant advantage lies in its recyclability and reusability. As companies shift towards sustainable packaging solutions, PP corrugated board stands out as a recyclable material that can be processed multiple times without degrading in quality. This feature encourages a circular economy, where resources are continuously reused, minimizing environmental impact. Furthermore, the potential for customization through advanced printing technologies allows businesses to enhance their branding while keeping sustainability at the forefront. With these advantages, PP corrugated board is proving to be an essential material in the evolution of eco-friendly packaging solutions.

How to Assess the Environmental Impact of Using PP Corrugated Board

Assessing the environmental impact of using PP corrugated board requires a multifaceted approach. This sustainable packaging solution stands out for its lightweight yet durable structure, significantly reducing transportation emissions. According to a report by Smithers Pira, PP corrugated board can lower carbon emissions by up to 30% compared to traditional materials like wood and paper. The recyclability of polypropylene further enhances its environmental credibility, offering a closed-loop system that minimizes waste.

When evaluating the sustainability of PP corrugated boards, consider the life cycle assessment (LCA). This method analyzes the environmental impact from raw material extraction through production, use, and disposal. In fact, a comprehensive LCA conducted by the European Plastics Converters Association revealed that PP corrugated boards consumed 20% less energy during production than their traditional counterparts.

Tips:

- Look for suppliers who offer PP corrugated boards made from post-consumer recycled materials to enhance sustainability.

- Implement a recycling program in your business to ensure that used boards are properly processed, aligning with circular economy principles.

- Regularly review your packaging solutions to incorporate innovations in materials that reduce environmental footprint even further.

How to Compare PP Corrugated Board with Traditional Packaging Materials

When comparing PP corrugated board with traditional packaging materials, it's essential to consider several factors, including durability, weight, and environmental impact. According to a report by Smithers Pira, the demand for lightweight packaging solutions is on the rise, with a projected growth rate of 4.8% annually. PP corrugated board weighs significantly less than traditional materials like cardboard, which reduces transportation costs and energy consumption during transit. This aspect is particularly vital in an age where logistics efficiency is critical.

Furthermore, PP corrugated board has excellent resistance to moisture and chemicals, making it ideal for various applications, from food packaging to industrial uses. A study from Freedonia Group indicates that the global market for corrugated packaging is expected to reach $257 billion by 2024, with PP boards gaining traction for their recyclability and long lifespan. This aligns with current sustainability trends where businesses seek eco-friendly alternatives that adhere to growing regulations regarding plastic use and waste. By choosing PP corrugated board, companies not only enhance their packaging strategy but also contribute positively to their environmental footprint.

Comparison of PP Corrugated Board with Traditional Packaging Materials

This chart compares the key attributes of PP corrugated board against traditional packaging materials such as cardboard and plastic. It highlights the advantages of using PP corrugated board in terms of durability, sustainability, and cost-effectiveness.

How to Enhance Product Protection with PP Corrugated Board Solutions

PP corrugated board is increasingly recognized as a superior packaging solution, particularly when it comes to enhancing product protection. The lightweight yet durable nature of polypropylene (PP) allows it to absorb impacts effectively, safeguarding the contents during transportation and storage. Its unique structure, composed of a fluted core sandwiched between two flat sheets, adds an extra layer of strength, which is essential for maintaining the integrity of fragile items.

Moreover, the water-resistant and chemical-resistant properties of PP corrugated board make it an ideal choice for a variety of industries. This makes it particularly suitable for products that may be exposed to moisture or harsh conditions, ensuring that the packaging remains intact and functional. Its customizability also allows for tailored solutions that meet specific requirements, whether for electronics, food, or delicate machinery. By opting for PP corrugated board, businesses can enhance their overall packaging strategy while simultaneously prioritizing sustainability and product safety.

How to Optimize Cost-Effectiveness Using PP Corrugated Board for Your Business

PP corrugated board has emerged as a smart packaging solution for businesses looking to balance sustainability with cost-effectiveness. By utilizing this versatile material, companies can significantly reduce their packaging costs while benefiting from its lightweight yet durable nature. The inherent properties of PP corrugated board allow for easier transportation and reduced shipping expenses, making it an economically viable choice for various applications.

To optimize cost-effectiveness, businesses can take advantage of PP corrugated board's versatility in design and functionality. Customization options enable companies to create tailored packaging solutions that meet their specific needs without compromising on quality. Moreover, the recyclable nature of PP corrugated board not only appeals to eco-conscious consumers but also helps businesses align with sustainable practices, potentially lowering waste disposal costs. By strategically implementing PP corrugated board, companies can enhance their operational efficiency while promoting an environmentally friendly image.

Related Posts

-

Exploring the Durability and Versatility of Colored Corrugated Plastic: Top 5 Industry Insights You Need to Know

-

Exploring the Future of Pp Corrugated Boxes at China Import and Export Fair 2025: Trends and Opportunities

-

What is the Best PP Corrugated Sheet and Why You Should Use It

-

Ultimate Guide to Sourcing White Corrugated Plastic: Everything Global Buyers Need to Know

-

How to Choose the Right Corrugated Plastic for Your Business Needs: Insights and Industry Statistics

-

Global Insights into Best Corrugated Plastic Totes with 2023 Import Export Certification Trends