- export5@runpingpp.com

- 24 Hours Online

Industry News

Top 10 Benefits of Pp Corrugated Sheets for Your Packaging Needs

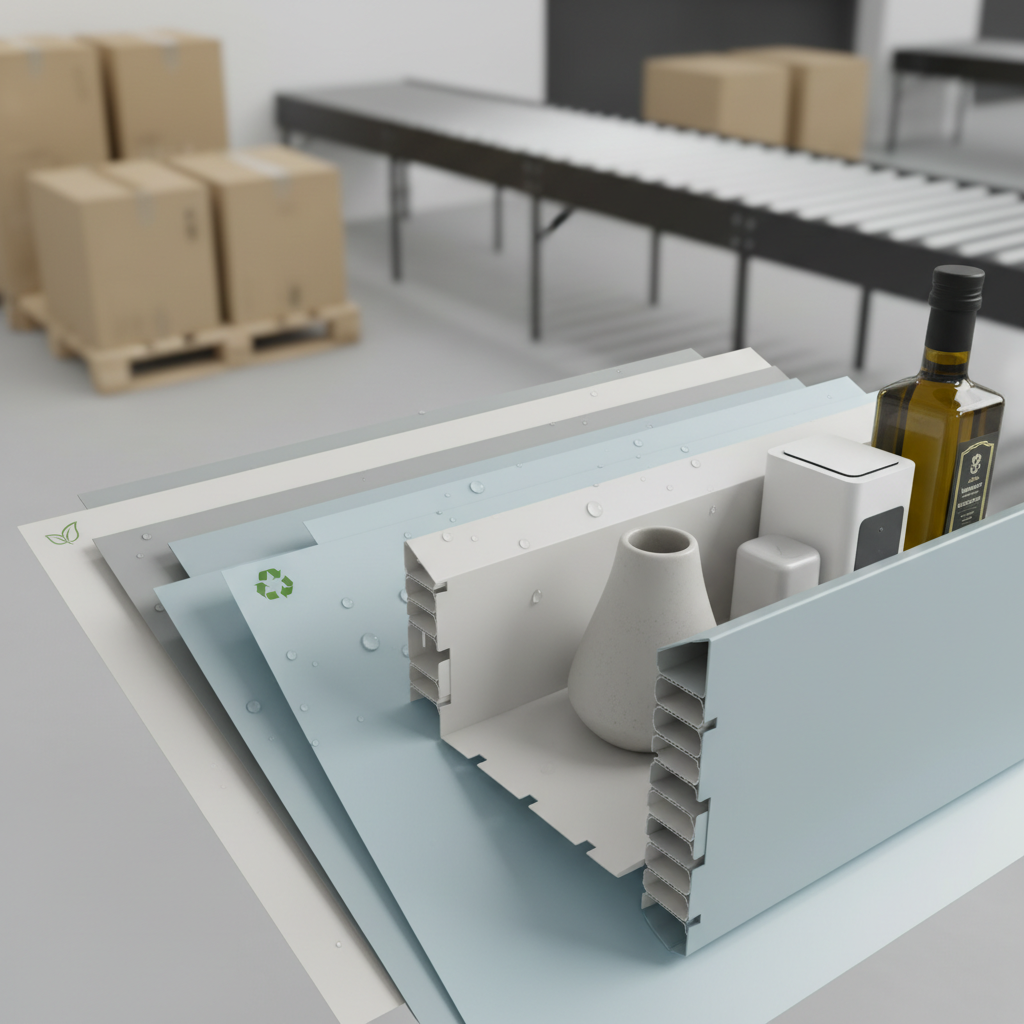

In the ever-evolving landscape of packaging solutions, Pp Corrugated sheets have emerged as a preferred choice for businesses seeking durability, versatility, and cost-effectiveness. These sheets, crafted from polypropylene, offer a unique combination of lightweight properties and exceptional strength, making them ideal for safeguarding products during transportation and storage. As industries continue to prioritize sustainability, Pp Corrugated sheets stand out not only for their performance but also for their eco-friendly characteristics, being fully recyclable and reducing environmental impact.

This article delves into the top 10 benefits of Pp Corrugated sheets, highlighting why they should be at the forefront of your packaging strategy. From their ability to withstand harsh conditions to their customizable nature, these sheets provide solutions that cater to a wide array of packaging needs. As we explore the advantages offered by Pp Corrugated materials, it becomes clear that investing in these sheets not only enhances product protection but also contributes to overall operational efficiency and brand reputation in a competitive market.

Advantages of Pp Corrugated Sheets in Packaging Efficiency

PP corrugated sheets have become increasingly popular in the packaging industry, primarily due to their exceptional efficiency in safeguarding products during transportation and storage. According to a report by Smithers Pira, the global market for corrugated packaging is projected to reach $300 billion by 2024, highlighting the growing reliance on materials that offer both durability and lightweight properties. PP corrugated sheets are known to be resistant to moisture, chemicals, and wear, making them an ideal choice for packaging that requires longevity and protection.

The efficiency of PP corrugated sheets extends beyond their protective capabilities. A study conducted by Freedonia Group reveals that the demand for sustainable packaging solutions has surged, with users favoring recyclable materials like PP over traditional cardboard alternatives. The use of PP sheets in packaging not only reduces material waste but also enhances efficiency in logistical processes, allowing for easier stacking and transportation. Additionally, these sheets are customizable in size and thickness, which further optimizes packaging operations and minimizes costs. Overall, the advantages of PP corrugated sheets in packaging efficiency are significant, driving innovation and sustainability within the industry.

Cost-Effectiveness of Pp Corrugated Sheets Compared to Alternative Materials

PP corrugated sheets offer significant cost advantages compared to alternative packaging materials like traditional cardboard and plastic. One of the primary reasons for their cost-effectiveness is their lightweight nature, which contributes to lower shipping fees and reduced fuel consumption during transportation. Unlike heavier materials, PP corrugated sheets help businesses cut costs while maintaining robust protection for their products. Additionally, their durability and resistance to moisture and chemicals minimize damage, which can translate into lower long-term expenses related to product replacement and customer complaints.

Moreover, the production of PP corrugated sheets typically requires less energy compared to energy-intensive materials like aluminum or glass. As industries increasingly focus on sustainability, this energy efficiency aligns perfectly with environmental goals, making PP sheets an eco-conscious option. Companies looking to balance cost and sustainability will find that PP corrugated sheets not only meet budgetary constraints but also support their green initiatives, strengthening their market position in an increasingly eco-aware consumer landscape.

This combination of affordability and reduced environmental impact makes PP corrugated sheets a wise choice for various packaging needs.

Durability and Strength: Performance Metrics of Pp Corrugated Sheets

PP corrugated sheets offer remarkable durability and strength that make them a popular choice for various packaging needs. Made from polypropylene, these sheets exhibit incredible resistance to physical stress, weather, and chemicals, ensuring that products remain safely packaged during transport and storage. The lightweight nature of PP corrugated sheets does not compromise their strength; instead, they provide an excellent balance between weight and load-bearing capacity, making them ideal for both industrial and retail applications.

In terms of performance metrics, PP corrugated sheets score highly with their ability to withstand impact and resist tearing. Their structural integrity ensures that they can endure heavy stacking without collapsing, which is crucial for warehouses and shipping facilities. Additionally, they are designed to be moisture-resistant, which prevents degradation in humid environments. This combination of features makes PP corrugated sheets a reliable choice for packaging goods that require a robust protective barrier. With varying thickness options available, these sheets can be tailored to meet specific packaging requirements, making them versatile for diverse product types.

Environmental Impact: Sustainability of Pp Corrugated Sheet Usage

The environmental impact of PP corrugated sheets makes them an excellent choice for sustainable packaging solutions. According to recent industry reports, the use of polypropylene (PP) materials can significantly reduce the carbon footprint associated with traditional packaging. PP corrugated sheets are not only lightweight and durable, but they also offer up to 90% recyclability, ensuring that they can be reused in various applications. The Plastic Industry Association states that recycling just one ton of PP can save approximately 2,800 pounds of carbon dioxide emissions, underscoring their eco-friendly advantages.

Tips for choosing sustainable packaging materials include assessing the lifecycle of each option. When selecting PP corrugated sheets, look for suppliers who prioritize recycled content and environmentally responsible processes. For maximum sustainability, consider utilizing these sheets in a closed-loop system—where post-consumer waste is collected and reused in manufacturing new sheets. Additionally, consider the sourcing of materials; opting for suppliers who use renewable energy in their production can further enhance the environmental benefits associated with your packaging choices.

By shifting towards PP corrugated sheets, businesses can not only meet their packaging needs but also contribute positively to environmental conservation efforts. Engaging in sustainable practices is vital in today’s eco-conscious market, where consumers increasingly favor brands that demonstrate a commitment to sustainability.

Versatility in Design: Applications of Pp Corrugated Sheets Across Industries

PP corrugated sheets have emerged as a versatile solution for packaging across various industries, owing to their lightweight yet durable nature. Their applications span from the agricultural sector, where they are used for packaging fruits and vegetables, to electronics, providing protective cases for delicate components. According to a report by Smithers Pira, the demand for PP corrugated materials in logistics and packaging is expected to grow at a CAGR of 4.5% between 2021 and 2026, reflecting their rising importance in efficient supply chains.

Tips: When using PP corrugated sheets, consider incorporating vibrant colors and custom designs to enhance brand visibility. This not only attracts customers but also reinforces brand identity throughout your packaging process. Additionally, implementing recyclable and eco-friendly practices with these materials can significantly contribute to sustainability goals, appealing to environmentally conscious consumers.

In the automotive industry, PP corrugated sheets serve as interior packaging for parts, ensuring they remain undamaged during transit. Their resistance to moisture and chemicals further positions them as an ideal choice for the food and beverage sector, where hygiene is paramount. By choosing PP corrugated sheets, companies are not just optimizing their packaging but also improving their operational efficiency while minimizing environmental impact.

Related Posts

-

Understanding the Benefits of Pp Corrugated for Sustainable Packaging Solutions

-

Future Market Insights and Trends for Best Corrugated PP by 2025 in the Packaging Industry

-

Understanding the Benefits of Corrugated Pp in Sustainable Packaging Solutions

-

Exploring the Environmental Benefits of Pp Corrugated Board in Sustainable Packaging Solutions

-

Ultimate Guide to Creating Effective Corrugated Signs for Your Business

-

How to Choose the Right Pp Corrugated Sheet for Your Business Needs