- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Best Pp Corrugated Sheets for Your Packaging Needs

When it comes to selecting materials for packaging, the choice of the right type can significantly impact both functionality and cost-effectiveness. Among the myriad options available, PP corrugated sheets have gained popularity due to their versatile properties and diverse applications. These sheets, made from polypropylene, are renowned for their durability, lightweight nature, and resistance to water and chemicals, making them an ideal solution for packaging needs across various industries.

In this introductory guide, we will explore the essential factors to consider when choosing the best PP corrugated sheets for your specific packaging requirements. From assessing the weight-bearing capabilities and thickness options to understanding the benefits of customization and recycling potential, we aim to provide you with comprehensive insights. Moreover, we will delve into the applications of PP corrugated sheets, highlighting how they can enhance your packaging strategy and contribute to efficient product protection and presentation. By the end of this exploration, you will be equipped with the knowledge to make informed decisions that align with your packaging goals.

Understanding the Basics of PP Corrugated Sheets in Packaging

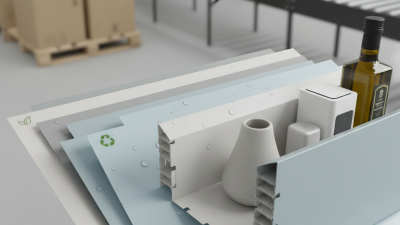

PP corrugated sheets are an important material used in the packaging industry, known for their lightweight yet sturdy composition. Made from polypropylene, these sheets consist of two flat surfaces with a fluted core that provides strength and resilience. Their unique structure not only allows for the protection of goods during transit but also makes them an eco-friendly choice, as they are recyclable and can be reused multiple times. Understanding the basic properties of PP corrugated sheets can help businesses make informed decisions when selecting packaging solutions that meet their specific needs.

One of the key advantages of PP corrugated sheets is their versatility. They come in various thicknesses and sizes, making them suitable for a wide range of applications, from shipping containers to dividers and point-of-sale displays. Additionally, they are resistant to moisture, chemicals, and UV light, enhancing their durability in different environments. Companies should consider these characteristics when evaluating their packaging options, ensuring that the materials chosen align with their product requirements, logistics, and sustainability goals.

How to Choose the Best PP Corrugated Sheets for Your Packaging Needs

| Property | Description | Typical Applications |

|---|---|---|

| Weight | Lightweight and easy to handle | Shipping materials, display stands |

| Durability | Resistant to moisture and impact | Outdoor signage, pallets |

| Customization | Available in various colors and sizes | Retail packaging, custom boxes |

| Environmentally Friendly | 100% recyclable material | Eco-friendly packaging solutions |

| Cost-Effectiveness | Lower material costs compared to cardboard | Bulk packaging, shipping boxes |

Identifying the Key Properties of PP Corrugated Sheets

When selecting the best PP corrugated sheets for packaging needs, it's essential to focus on their key properties, which significantly influence their performance and suitability. Polypropylene (PP) is known for its excellent durability and lightweight characteristics, making it a preferred choice in various industries. According to a 2022 report by the Packaging Industry Association, the global demand for polypropylene-based packaging solutions is projected to grow by 6.5% annually, underscoring its essential role in modern packaging.

One of the primary properties of PP corrugated sheets is their strength-to-weight ratio. These sheets exhibit remarkable rigidity, which enables them to provide adequate protection for products during storage and transit. Industry studies indicate that the load-bearing capacity of PP corrugated sheets can be up to three times that of conventional cardboard, which enhances their usability across sectors like electronics, automotive, and food packaging. Additionally, they are resistant to moisture and chemicals, making them ideal for packaging in environments where conventional materials may fail.

Another critical property to consider is the environmental impact of the materials. PP corrugated sheets are recyclable and can significantly reduce waste in packaging applications. Research from the Sustainable Packaging Coalition has shown that shifting to recycled PP for packaging could decrease carbon emissions by up to 20% compared to using virgin materials. Therefore, when choosing PP corrugated sheets, both their physical properties and sustainability potential are key factors that can help businesses meet their packaging goals effectively.

Evaluating Different Thickness and Flexibility for Your Needs

When selecting the best PP corrugated sheets for your packaging needs, understanding the attributes of thickness and flexibility is crucial. The International Corrugated Case Association (ICCA) notes that the thickness of PP corrugated sheets typically ranges from 2mm to 10mm. Thicker sheets provide more durability and impact resistance, making them suitable for heavy-duty applications, such as shipping fragile items. On the other hand, sheets with lower thickness are lightweight and offer easier handling and cost-effectiveness, ideal for industries that require regular shipments of lightweight products.

Flexibility is another essential factor when evaluating PP corrugated sheets. A report by Smithers Pira indicates that flexibility allows sheets to be easily folded or shaped for specific packaging needs without compromising their structural integrity. This characteristic is particularly advantageous in industries such as retail, where packaging visually appealing designs is paramount. Utilizing flexible sheets can also reduce storage space as they can be easily stacked or stored flat when not in use. As you assess your packaging requirements, consider how the balance of thickness and flexibility in PP corrugated sheets can optimize both protection and presentation of your products.

Comparing Costs and Suppliers of PP Corrugated Sheets

When selecting PP corrugated sheets for packaging needs, a critical factor to consider is the cost and the reliability of the suppliers. Prices can vary significantly based on the thickness, size, and customization of the sheets. Therefore, it is essential to gather quotes from multiple suppliers and analyze these costs in relation to your specific packaging requirements. This process not only helps in budgeting but also in identifying suppliers that offer the best value for money.

Additionally, evaluating suppliers involves looking beyond just the price. Factors such as the quality of the corrugated sheets, delivery times, and customer support capabilities play a crucial role in making the right decision. Conducting thorough research on potential suppliers can reveal important insights, including reviews from other customers and their capacity to meet bulk orders. By comparing these aspects, businesses can ensure they select a supplier that aligns both with their financial constraints and quality expectations, ultimately supporting their packaging objectives efficiently.

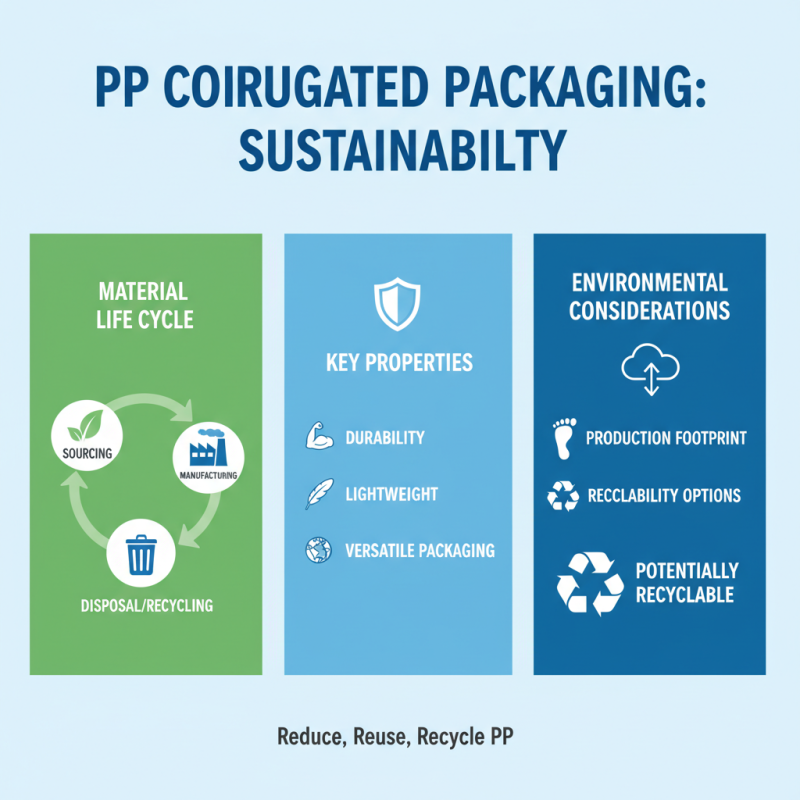

Assessing Environmental Impact and Recyclability Options

When selecting pp corrugated sheets for packaging, understanding their environmental impact and recyclability options is crucial. Polypropylene, the material used in these sheets, is known for its durability and lightweight properties, making it a popular choice for various packaging solutions. However, the environmental footprint of its production and disposal is a significant consideration. It is essential to evaluate the life cycle of the material, from sourcing and manufacturing to eventual disposal or recycling, to fully understand its impact on the environment.

Recyclability is a key factor when choosing the right packaging materials. PP corrugated sheets can often be reused and recycled, which is advantageous for companies aiming to minimize waste. Many recycling facilities accept polypropylene materials, meaning that once these sheets have served their purpose, they can be processed into new products. Furthermore, looking for sheets with standardized recycling symbols can facilitate proper disposal and encourage responsible consumption. By prioritizing materials with high recyclability rates, businesses can not only improve their sustainability practices but also appeal to eco-conscious consumers.

Related Posts

-

Understanding the Benefits of Pp Corrugated for Sustainable Packaging Solutions

-

Exploring the Environmental Benefits of Pp Corrugated Board in Sustainable Packaging Solutions

-

Top 10 Benefits of Pp Corrugated Sheets for Your Packaging Needs

-

Ultimate Tips for Choosing the Right Pp Corrugated Bin for Your Needs

-

Exploring the Surge in Pp Corrugated Box Demand at the Successful 137th Canton Fair

-

Ultimate Checklist for Choosing the Best Corrugated PP Products for Your Business Needs