- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Best Pp Corrugated Box for Your Packaging Needs

In the ever-evolving landscape of packaging solutions, the Pp Corrugated Box has gained tremendous popularity due to its versatility and durability. According to industry expert Dr. Emily Carter, a leading figure in sustainable packaging innovations, “Choosing the right packaging is not just about protection; it’s also about enhancing brand value.” This insight underscores the importance of selecting the appropriate Pp Corrugated Box tailored to your specific needs.

The choice of packaging can significantly impact the efficiency of your shipping, storage, and overall customer satisfaction. Pp Corrugated Boxes, known for their lightweight and strong characteristics, offer unparalleled protection for various products while also being cost-effective. As businesses strive to optimize their supply chains, understanding the distinct features and benefits of different box designs becomes crucial.

Ultimately, making an informed decision about Pp Corrugated Boxes can elevate your packaging strategy, ensure product safety, and resonate with environmentally conscious consumers. In this article, we will explore key considerations, materials, and features to help you select the best Pp Corrugated Box for your packaging needs.

Understanding the Basics of PP Corrugated Boxes

PP corrugated boxes are a popular choice in the packaging industry due to their lightweight yet durable nature. Made from polypropylene, these boxes provide excellent protection against moisture and various environmental factors, making them suitable for shipping a wide range of products. Understanding the basic characteristics of PP corrugated boxes can help you make informed decisions when selecting the right packaging solution for your needs.

When considering PP corrugated boxes, one important aspect is the thickness and flute size of the material, as these factors determine the box's strength and rigidity. For heavier items, thicker and larger flutes are typically recommended, while lighter items can be safely packaged using thinner, smaller flutes.

Tips: Always check the weight capacity of the box to ensure that it can securely hold your product without risk of damage during transit. Also, consider the environmental conditions the box will face; if it will be stored in damp areas, opting for water-resistant coatings can be beneficial.

Additionally, customization options such as printing and sizing should be taken into account. Many manufacturers offer a range of sizes to fit your products perfectly, while printing capabilities allow for brand visibility and information to be clearly displayed.

Tips: When customizing, think about the design elements that will attract your target audience, ensuring your packaging stands out while being functional. Always sample and test the box's durability before large-scale production to ensure it meets your specific requirements.

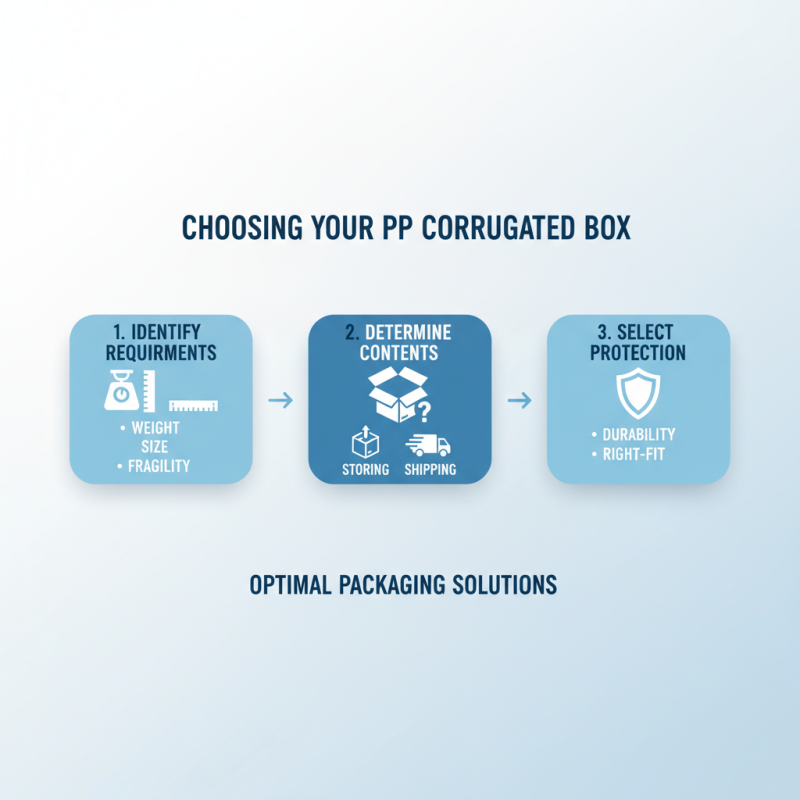

Identifying Your Packaging Requirements

When choosing the best PP corrugated box for your packaging needs, the first step is to clearly identify your packaging requirements. Consider what you will be storing or shipping and evaluate factors such as weight, size, and fragility. Understanding these factors will help you select a box that offers the right level of protection and durability for your items.

Tips: Always measure your products accurately to ensure that you choose the right dimensions for your boxes. This helps to avoid excess movement and potential damage during transit. Additionally, think about whether your items need to be stacked and if so, opt for boxes with reinforced corners for added stability.

Another consideration is the environment in which your packaging will be used. Will it be exposed to moisture, heat, or pressure? PP corrugated boxes are versatile, but not all are created equal. Assess the conditions your packaging will face to ensure you select a suitable material that maintains its integrity under those circumstances.

Tips: Conduct a simple test by placing your items in different box types to see which offers the best fit and protection before making a bulk purchase. This hands-on approach will help you make a more informed decision, ensuring that your packaging meets your operational demands effectively.

Evaluating Different Types of PP Corrugated Boxes

When evaluating different types of PP corrugated boxes for your packaging needs, it's essential to consider the material's durability and sustainability. PP (polypropylene) is known for its lightweight yet strong properties, making it a preferred choice for a variety of applications. These boxes can efficiently protect contents against moisture, dust, and impact, ensuring that items remain safe during transit and storage. Assessing the thickness and flute size of the corrugated layers can provide insights into their load-bearing capabilities and overall sturdiness, which is crucial for heavier or fragile products.

Another important factor is the design flexibility offered by PP corrugated boxes. They can be easily customized in terms of size, shape, and printing options, catering to diverse branding and logistical requirements. Businesses may choose between standard designs or opt for tailored solutions that enhance functionality and presentation. Additionally, consider whether the boxes are recyclable or reusable, as sustainability continues to play a significant role in packaging decisions. By examining these elements, you can select a type of PP corrugated box that not only meets your packaging specifications but also aligns with your environmental goals.

How to Choose the Best PP Corrugated Box for Your Packaging Needs - Evaluating Different Types of PP Corrugated Boxes

| Box Type | Dimensions (mm) | Weight Capacity (kg) | Color Options | Flute Type | Ideal Use |

|---|---|---|---|---|---|

| Single Face | 300 x 200 x 150 | 5 | White, Blue, Yellow | A Flute | Inner packaging, Light items |

| Double Wall | 600 x 400 x 350 | 25 | Brown, Green | C Flute | Heavy items, Shipping |

| Octagonal Box | 400 x 400 x 400 | 20 | White, Custom colors | B Flute | Retail packaging, Gifts |

| Folding Box | 500 x 300 x 200 | 10 | Brown | E Flute | Lightweight products, Storage |

Comparing Prices and Suppliers for Cost-Effectiveness

When selecting the best PP corrugated box for your packaging needs, comparing prices and suppliers is crucial for achieving cost-effectiveness. This lightweight yet durable packaging solution is favored by businesses, but costs can vary significantly depending on the supplier. Researching multiple suppliers provides a broader understanding of the market, helping you find the best price without compromising on quality. Aim to seek out quotes from at least three different suppliers to gauge a fair pricing range.

Tips for cost-effectiveness include considering bulk orders. Many suppliers offer discounts on larger quantities, which can significantly lower the cost per unit. Additionally, factor in shipping costs as they can inflate the overall expense. Always check if the supplier provides free shipping for larger orders or ways to minimize these costs. Lastly, don’t overlook the importance of value over price; sometimes a slightly higher upfront cost can lead to better materials and durability, ultimately saving you money in the long run by reducing damage during transport.

Comparative Analysis of Pp Corrugated Box Prices by Supplier

This chart represents the price comparison of PP corrugated boxes from various suppliers, allowing businesses to choose the best cost-effective options for their packaging needs.

Assessing Environmental Impact and Recyclability Options

When selecting a PP corrugated box, considering its environmental impact and recyclability is essential for businesses that aim to adopt sustainable packaging solutions. According to a report by the European Commission, packaging waste contributes significantly to environmental degradation, with over 27 million tons generated in the EU alone in 2020. Choosing recyclable materials can help mitigate these effects, and PP corrugated boxes offer a promising alternative, as they are made from a recyclable thermoplastic polymer, which allows them to be reused and recycled effectively.

The recyclability of PP corrugated boxes is not just an environmental concern but also an economic one. The National Association for Plastic Container Recovery (NAPCOR) states that polypropylene has a recycling rate of about 5% in the US, which, while low, indicates a growing trend towards improved recycling infrastructures. Many municipalities are beginning to accept PP materials in their recycling programs, enhancing the feasibility of recycling these boxes. Additionally, organizations like the Environmental Protection Agency emphasize the importance of utilizing materials that can be easily recycled and integrated back into the production cycle, further supporting the case for PP corrugated boxes in terms of sustainability.

Related Posts

-

Exploring the Surge in Pp Corrugated Box Demand at the Successful 137th Canton Fair

-

Innovative Uses of Best Corrugated Pp Box in Various Industries Around the Globe

-

The Ultimate Guide to Understanding Corrugated Pp Box Features Benefits and Applications

-

What is a Pp Corrugated Plastic Box and Why is it Your Best Packaging Solution?

-

Exploring the Impact of Pp Corrugated Sheet Innovations at the 138th Canton Fair 2025 in China

-

Exploring the Future of Pp Corrugated Boxes at China Import and Export Fair 2025: Trends and Opportunities