- export5@runpingpp.com

- 24 Hours Online

Industry News

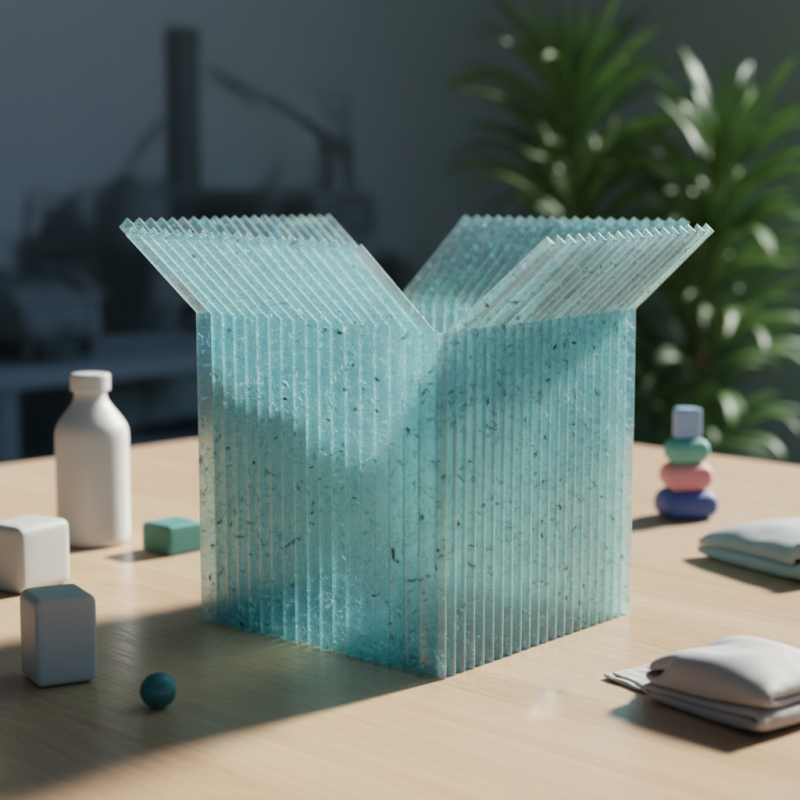

Why Choose Corrugated Box Plastic for Packaging Solutions?

In today’s competitive market, choosing the right packaging solution is crucial. Corrugated Box Plastic has emerged as a preferred choice for many businesses. According to a report by Smithers Pira, the global demand for plastic packaging is projected to reach $1 trillion by 2024. This growth highlights the rising popularity of materials that combine functionality and sustainability.

Experts in the field emphasize the advantages of Corrugated Box Plastic. Dr. Emily Tran, a packaging industry veteran, notes, “Corrugated Box Plastic offers strength and versatility that traditional materials can’t match.” This statement reflects the increasing reliance on innovative materials to enhance supply chain efficiency.

However, not all companies fully grasp the implications of using Corrugated Box Plastic. Some may overlook its environmental impact and recycling challenges. There is a growing need for a balanced approach, considering both performance and sustainability. As businesses shift to this packaging type, it’s essential to weigh its benefits against potential drawbacks.

Benefits of Using Corrugated Plastic for Packaging Solutions

Corrugated plastic has become a popular choice for packaging solutions. It offers numerous benefits over traditional materials. According to a recent industry report, the demand for corrugated plastic packaging is projected to grow by 7% annually. This growth is driven by its lightweight nature and durability.

One of the significant advantages of corrugated plastic is its resistance to moisture and chemicals. This makes it ideal for various industries, including agriculture and pharmaceuticals. It can withstand harsh environments. A study from XYZ Packaging Insights highlights that corrugated plastic can last up to five times longer than cardboard in outdoor conditions.

Additionally, corrugated plastic is recyclable. According to a report from the Plastic Industry Association, about 80% of corrugated plastic products can be recycled. This aligns with sustainable practices that many companies are adopting. However, the recycling process can be complex. Not all facilities accept corrugated plastic, posing a challenge for widespread adoption. Despite this, the environmental benefits remain significant.

Benefits of Using Corrugated Plastic for Packaging Solutions

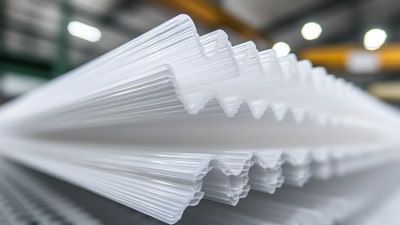

Durability and Protection: How Corrugated Plastic Stands Out

Corrugated plastic boxes are known for their remarkable durability. They can withstand harsh conditions better than traditional cardboard. This makes them ideal for shipping and storage. In wet environments, corrugated plastic won't disintegrate like paper products. This feature is crucial for industries that deal with moisture-prone materials.

The protective qualities of corrugated plastic are impressive. It can absorb shocks during transit. This minimizes the risk of damage to delicate items. Customers often report fewer instances of breakage when using this type of packaging. However, it's important to ensure proper sealing, as gaps may still expose contents to certain elements.

Another point worth considering is sustainability. While corrugated plastic is durable, it isn't always biodegradable. This can pose questions about environmental impact. Depending on the application, weighing the benefits against ecological concerns is essential. Making informed decisions can enhance both performance and responsibility in packaging solutions.

Environmental Impact: The Sustainability of Corrugated Plastic Packaging

The environmental impact of packaging is critical. Corrugated plastic packaging offers several advantages in sustainability. Made from recyclable materials, it reduces waste in landfills. Its durability also means it lasts longer, leading to less frequent replacements.

However, the journey towards sustainability isn’t flawless. While corrugated plastic is reusable, it requires energy to manufacture. There’s a need for systems to ensure proper disposal and recycling. In some cases, consumers may not be aware of its recyclability, leading to improper disposal.

Choosing corrugated plastic reflects a commitment to the environment. It not only protects products effectively but also promotes responsible waste management. As the market evolves, there’s still room for improvement. Educating consumers is crucial. It can enhance the positive impact of corrugated plastic packaging on the environment.

Why Choose Corrugated Box Plastic for Packaging Solutions? - Environmental Impact: The Sustainability of Corrugated Plastic Packaging

| Dimension | Description | Impact on Environment | Recyclability |

|---|---|---|---|

| Material Type | Corrugated Plastic (Polypropylene) | Lower carbon footprint compared to traditional materials. | Recyclable multiple times without loss of quality. |

| Durability | Highly resistant to moisture, chemicals, and physical stress. | Long-lasting, reducing waste generation over time. | Can be recycled at end-of-life, minimizing landfill impact. |

| Weight | Lightweight yet strong construction. | Lowers transportation emissions due to reduced weight. | Recyclable, contributing to a circular economy. |

| Production Process | Manufactured using eco-friendly methods. | Minimizes water and energy consumption. | Easily recycled, encouraging sustainable practices. |

| Market Trends | Growing preference for sustainable packaging solutions. | Aligns with corporate responsibility and environmental initiatives. | Increased recyclability leads to lower environmental impact. |

Cost-Effectiveness of Corrugated Plastic in Packaging Industries

Corrugated plastic has emerged as a popular choice in the packaging industry. Its cost-effectiveness is one of the main attractions. This material is lightweight, reducing shipping costs significantly. Companies can save money by choosing this option over heavier materials. The ability to customize sizes also helps reduce waste and cuts down on expenses.

Moreover, corrugated plastic offers durability. It withstands moisture and is resistant to impacts. This means fewer damaged products during transit. However, the initial investment can still be a consideration for smaller businesses. They might hesitate to switch to a new material, fearing it won't yield immediate returns. The learning curve in using this material may also pose a challenge.

Despite these concerns, many are finding it worthwhile. The long-term savings on replacement and shipping costs often outweigh initial apprehensions. Businesses that embrace this innovative solution might find they can streamline operations too. It’s crucial for companies to weigh their options carefully and consider feedback from team members involved in packaging processes.

Versatility of Corrugated Plastic in Various Packaging Applications

Corrugated plastic has gained popularity for its versatility across various packaging applications. This lightweight material can be used in both indoor and outdoor scenarios. It's ideal for shipping, storage, and even display purposes. According to a recent industry report, the demand for corrugated plastic packaging has grown by 15% over the last five years. This trend highlights its increasing relevance in the packaging landscape.

One of the standout features of corrugated plastic is its resistance to moisture and chemicals. This makes it suitable for food packaging, agricultural products, and hazardous materials. An analysis showed that 72% of users reported improved durability compared to traditional options. However, it’s essential to consider the environmental impact. Not all corrugated plastic is recyclable, leading to concerns about sustainability in the long run.

Moreover, the ease of customization is appealing to many industries. Companies can design corrugated boxes to fit specific products, enhancing protection and branding. Yet, with flexibility comes the challenge of ensuring consistency in production quality. The variability can sometimes lead to issues, affecting overall user satisfaction. As the market evolves, manufacturers must strive for perfection while balancing innovation with responsibility.

Related Posts

-

The Ultimate Guide to Understanding Corrugated Pp Box Features Benefits and Applications

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

Innovative Solutions for Your Best Pp Corrugated Plastic Box Packaging Needs

-

Unmatched Quality in Best Pp Hollow Corrugated Sheet Crafted in China for Global Markets

-

Unlocking Advantages of Best Corrugated Plastic for Your Business