- export5@runpingpp.com

- 24 Hours Online

Industry News

Top Tips for Choosing Corrugated Box Plastic for Packaging?

In the world of packaging, selecting the right materials is crucial. Corrugated Box Plastic is gaining popularity for its durability and lightweight characteristics. According to a recent report from Smithers Pira, the global demand for plastic packaging, including corrugated options, is projected to grow by 4.5% annually through 2025. Industry expert Dr. Emily Chang states, "Choosing the right Corrugated Box Plastic can significantly impact both cost-efficiency and environmental sustainability."

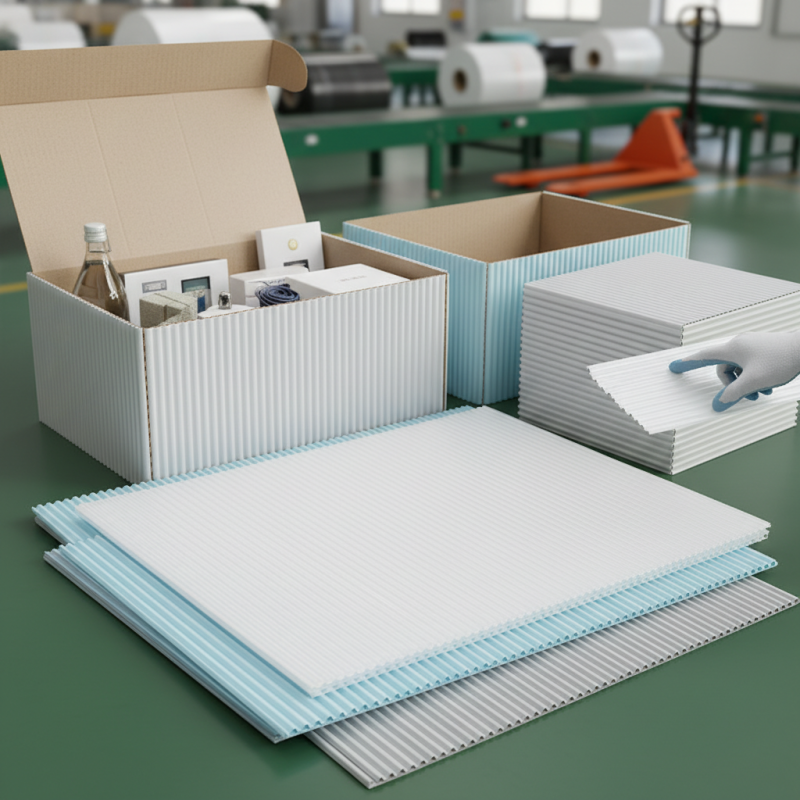

As businesses seek sustainable alternatives, Corrugated Box Plastic stands out. It offers moisture resistance and protection during transit. Yet, not all options are created equal. Factors like thickness, manufacturing methods, and recyclability should be carefully considered. Many companies overlook these elements. This oversight can lead to increased costs and waste in the long run.

Engaging with professionals in the field can provide valuable insights. However, businesses must also be aware of their unique packaging needs. An informed decision about Corrugated Box Plastic may require revisiting initial assumptions. Balancing function and cost-effectiveness is vital in today's competitive landscape.

Understanding the Importance of Corrugated Box Plastic in Packaging

Corrugated box plastic plays a crucial role in modern packaging. It combines durability and lightweight properties. This unique material protects products from damage during shipping. It's essential to choose the right type for your needs.

When selecting corrugated box plastic, consider the thickness. Thicker materials offer better protection. However, they can add to shipping costs. Balance is key. Evaluate the products you’re packaging to determine the necessary thickness.

Another tip is to assess water resistance. Some corrugated plastics are designed to repel moisture. This is particularly important for perishable goods. Remember, packaging should reflect the product's quality. A poorly chosen material can affect your brand image. Think critically about your options to ensure you make the best choice.

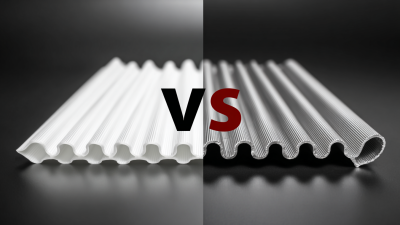

Evaluating Material Types: Polyethylene vs. Polypropylene for Durability

When choosing corrugated box plastic for packaging, it’s essential to evaluate the right material type. Polyethylene and polypropylene are two popular options. Polyethylene is known for its flexibility. It’s often used in applications requiring durability. However, it can be susceptible to UV degradation over time. This means it may not be suitable for long-term use outdoors.

On the other hand, polypropylene offers impressive strength and resistance to chemicals. It can withstand higher temperatures than polyethylene. This makes it a great choice for industrial applications. Still, it can be more rigid, which may not be suitable for all packaging needs. Every choice has its trade-offs. One material may excel in durability while lacking flexibility. Understanding the specific requirements of your packaging will guide you to the right decision. In practice, many users find themselves altering their initial choices after testing materials under real conditions. This reflection is crucial in optimizing packaging solutions.

Top Tips for Choosing Corrugated Box Plastic for Packaging

| Material Type | Durability | Weight | Cost | Flexibility |

|---|---|---|---|---|

| Polyethylene (PE) | High resistance to impact and moisture | Lightweight | Generally lower | Moderate flexibility |

| Polypropylene (PP) | Excellent strength and rigidity | Slightly heavier | Moderate cost | Lower flexibility |

| Polyethylene Terephthalate (PET) | High durability and strength | Lightweight | Higher cost | Moderate flexibility |

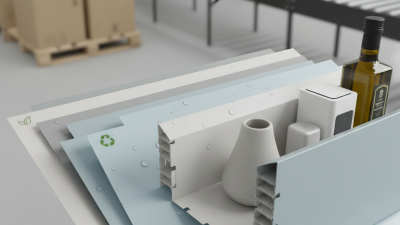

Assessing Environmental Impact: Recyclability of Corrugated Plastics

When selecting corrugated plastic for packaging, recyclability is a critical factor. Assessing the environmental impact of materials can help mitigate waste. Corrugated plastics are known for their durability. However, not all types are created equal regarding recyclability. Some may not break down easily, leading to significant landfill issues.

Recycled corrugated plastics are often repurposed into new products. This circular approach reduces the need for virgin materials. Yet, many consumers are unaware of local recycling capabilities. This lack of knowledge can hinder effective recycling efforts, creating more challenges. Identifying appropriate local facilities is essential for proper disposal.

Additionally, the initial cost of high-recyclability plastics might deter businesses. Balancing sustainability and budget constraints is tough. While investing in these materials could seem expensive, the long-term benefits might outweigh short-term savings. The reality is that choosing the right packaging is not just about cost; it’s about our impact on the environment.

Understanding recyclability leads to more informed decisions, ultimately benefiting our planet.

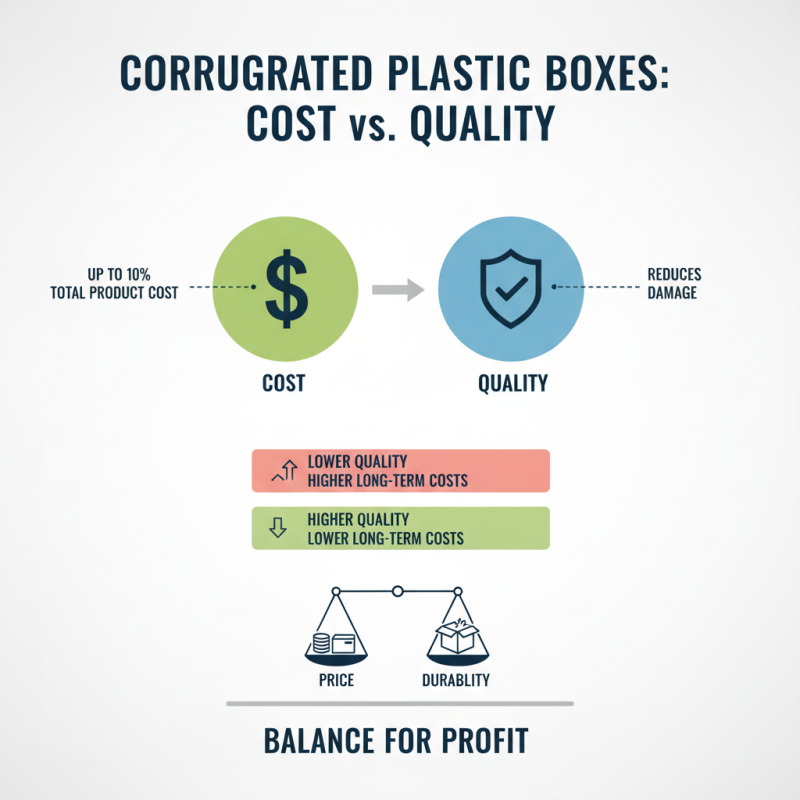

Cost Analysis: Balancing Quality and Price in Packaging Solutions

Choosing the right corrugated box plastic can be challenging. Cost is often a primary concern. According to a recent industry report, packaging costs can account for up to 10% of total product costs. Balancing quality with price is crucial. Lower-quality materials often lead to higher damage rates during transit, which can increase total costs in the long run.

The price of corrugated box plastic varies significantly. Factors include material thickness, size, and manufacturing methods. Premium options, while more expensive, often offer better protection. A study highlighted that 35% of businesses reported increased sales when they invested in better packaging. However, many small companies hesitate to spend on quality due to tight budgets. This raises a question of sustainability. Does saving on packaging lead to higher costs elsewhere?

A detailed cost analysis is essential. Evaluate not just the purchase price, but also the longevity and performance of the materials. Sometimes, the cheapest option ends up being the most expensive choice. Relying on price alone may overlook important factors like durability and user experience. In a competitive market, thoughtful investment in packaging can set a company apart.

Industry Standards: Compliance and Regulations for Packaging Materials

When selecting corrugated box plastic for packaging, understanding industry standards is essential. Compliance with regulations ensures safety and effectiveness. Different regions have varying guidelines for materials used in packaging. It’s crucial to stay informed about these regulations. Ignoring them could lead to serious repercussions for businesses and consumers alike.

One tip is to check if the packaging materials are recyclable. This can impact your brand's reputation. Sustainable practices are becoming important to consumers. Adopt materials that meet environmental standards. Additionally, verify if the plastic complies with food-safe regulations if it will hold edible products.

Testing the durability of the packaging is an often-overlooked step. Doesn’t it seem logical? Whether during transportation or storage, strong packaging reduces risks of damage. Remember to assess thickness and resistance to environmental factors. If it fails, the product may not reach its destination intact. These reflections are vital for creating reliable packaging solutions.

Related Posts

-

7 Reasons Why the Best Pp Corrugated Plastic Box Outperforms Traditional Packaging Solutions Globally

-

Issues with Sourcing Corrugated Box Plastic Solutions for International Buyers

-

Ultimate Comparison: Why the Best Plastic Corrugated Sheet Stands Out Among Competitors

-

Top 10 Benefits of Pp Corrugated Sheets for Your Packaging Needs

-

Unmatched Quality in Best Pp Hollow Corrugated Sheet Crafted in China for Global Markets

-

Exploring the Impact of Pp Corrugated Sheet Innovations at the 138th Canton Fair 2025 in China