- export5@runpingpp.com

- 24 Hours Online

Industry News

Why Choose Pp Hollow Corrugated Sheet for Your Packaging and Construction Needs

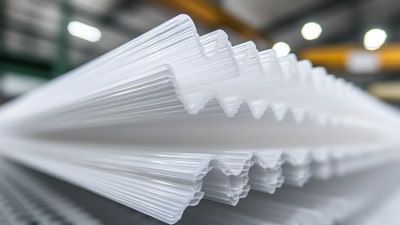

In the rapidly evolving landscape of packaging and construction, materials that offer both durability and versatility are becoming increasingly essential. One such material that has garnered significant attention is the Pp Hollow Corrugated Sheet. According to a recent market analysis by Smithers Pira, the global demand for sustainable packaging solutions is projected to grow at an annual rate of 4.8% from 2021 to 2026, driving manufacturers towards innovative materials that can meet eco-friendly criteria. Pp Hollow Corrugated Sheets stand out as an ideal choice due to their lightweight yet robust structure, which significantly reduces shipping costs and environmental impact while ensuring product safety.

Furthermore, these sheets have proven effective in various construction applications, including temporary barriers, signage, and insulation. A report from Allied Market Research indicates that the construction sector is expected to reach $10.3 trillion by 2023, with an increasing focus on efficient and sustainable materials. The Pp Hollow Corrugated Sheet fits perfectly into this trend, offering excellent moisture resistance and recyclability, making it an appealing option for both packaging professionals and construction companies aiming to enhance their sustainability efforts. As industries strive to reduce their carbon footprint and adopt more innovative solutions, the Pp Hollow Corrugated Sheet emerges as a frontrunner in driving both economic and environmental benefits.

Benefits of Using Pp Hollow Corrugated Sheets in Packaging

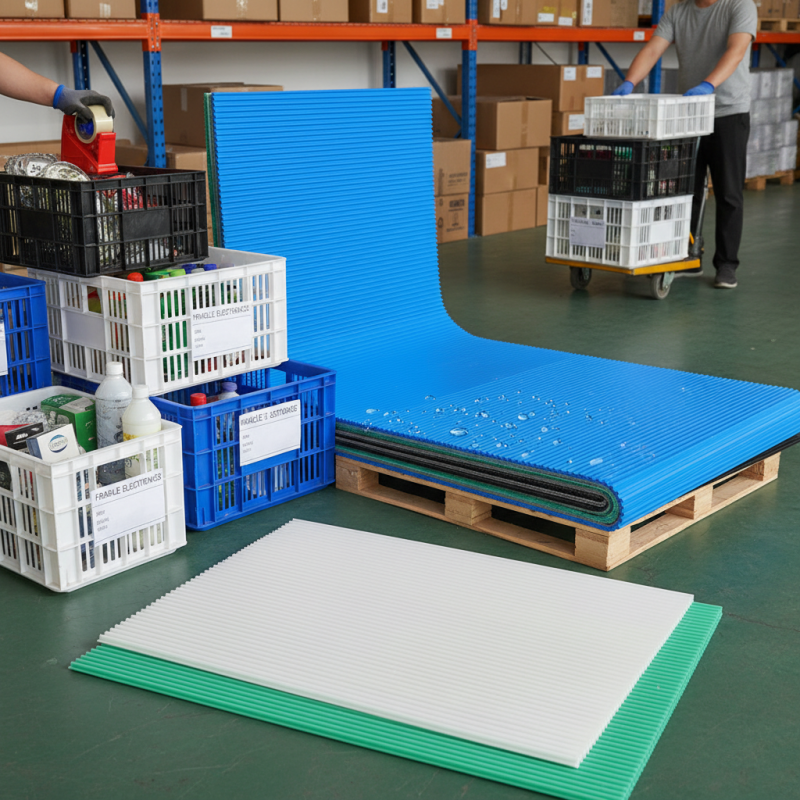

PP hollow corrugated sheets have become an increasingly popular choice for packaging due to their unique combination of durability and lightweight characteristics. These sheets are made from polypropylene, making them resistant to moisture, chemicals, and wear, which is essential for protecting products during shipping and storage. Additionally, their hollow structure provides enhanced insulation and shock absorption, allowing for safer transport of fragile items.

When considering packaging solutions, it's crucial to maximize efficiency. Tips for utilizing PP hollow corrugated sheets effectively include customizing sizes to fit products snugly, which can reduce wasted space and costs. Additionally, their recyclability makes them an environmentally friendly option, appealing to businesses keen on sustainable practices. Furthermore, the ability to print graphics directly onto the sheets allows for improved branding opportunities while ensuring that your packaging stands out.

In construction, these sheets serve as excellent barriers and supports, offering flexibility and strength at a lower weight compared to traditional materials. Their ability to withstand varying weather conditions makes them ideal for temporary structures and signage. For any project, ensuring that you choose the right thickness and dimensions according to your specific requirements will enhance performance and longevity. By leveraging the benefits of PP hollow corrugated sheets, companies can elevate their packaging solutions and construction methods effectively.

Durability and Strength: Key Features of Pp Hollow Corrugated Sheets

Pp hollow corrugated sheets are increasingly becoming the go-to solution for various packaging and construction needs, primarily due to their remarkable durability and strength. Made from high-density polypropylene, these sheets exhibit outstanding resilience against physical impacts, making them ideal for environments that demand robust protective materials. Their lightweight nature combined with impressive load-bearing capabilities allows for easy handling and transportation, without compromising on structural integrity. This unique combination positions pp hollow corrugated sheets as an excellent choice for both temporary and permanent installations.

In addition to their strength, these sheets are highly resistant to moisture, chemicals, and extreme weather conditions. This resistance not only prolongs the lifespan of the materials used in packaging and construction but also ensures minimal maintenance over time. The versatility of pp hollow corrugated sheets extends to a wide range of applications, from protective packaging for fragile items to serving as durable barriers in construction projects. This ability to withstand challenging conditions while delivering reliable performance makes pp hollow corrugated sheets an indispensable asset in various industries, meeting the needs of modern packaging and construction with ease.

Cost-Effectiveness of Pp Hollow Corrugated Sheets in Construction

Pp hollow corrugated sheets have emerged as a game-changer in the realm of construction due to their exceptional cost-effectiveness. Made from polypropylenes, these sheets offer a lightweight yet durable alternative to traditional materials. Their ability to withstand various environmental conditions without significant wear and tear makes them an economically sound investment for both short-term and long-term projects. Consequently, builders and contractors are increasingly turning to these sheets not only to reduce initial costs but also to minimize maintenance expenses over the lifespan of their applications.

Furthermore, the production process of pp hollow corrugated sheets is more efficient compared to conventional materials, resulting in lower manufacturing costs that translate into savings for purchasers. The versatility of these sheets also allows for a wide range of applications, be it for temporary structures, signage, or packaging needs, which further emphasizes their economic viability. By adopting pp hollow corrugated sheets, construction professionals can enhance the sustainability of their projects while keeping costs within budget, ultimately making these sheets a wise choice for any construction endeavor.

Environmental Impact and Sustainability of Pp Hollow Corrugated Sheets

PP hollow corrugated sheets are gaining popularity in packaging and construction due to their positive environmental impact and sustainable characteristics. As a lightweight yet durable material, these sheets are often made from recyclable polypropylene, which contributes to a reduced carbon footprint compared to traditional packaging solutions. Their production involves less energy consumption, making them a more environmentally friendly option for businesses looking to minimize their ecological impact.

Moreover, PP hollow corrugated sheets are fully recyclable, which promotes a circular economy. After their lifecycle in packaging or construction, they can be reprocessed into new sheets or other products, reducing the amount of waste sent to landfills. This inherent recyclability makes PP sheets an attractive choice for companies devoted to sustainable practices, as they can ensure that their materials are reused rather than discarded. By choosing these sheets, businesses not only enhance their own sustainability efforts but also contribute to a larger movement towards environmentally responsible construction and packaging solutions.

Applications of Pp Hollow Corrugated Sheets in Various Industries

PP hollow corrugated sheets have become a popular choice across various industries due to their versatility and durability. In the packaging sector, these sheets offer an excellent alternative to traditional materials. They are lightweight yet robust, providing reliable protection for products during transit and storage. Their water-resistant properties also make them suitable for outdoor applications, ensuring that the contents remain safe from environmental elements.

In construction, the applications of PP hollow corrugated sheets are equally compelling. They are often used as temporary wall partitions, providing an effective solution for site management while ensuring visibility and airflow. Additionally, these sheets serve as excellent shuttering boards for concrete, facilitating a smoother construction process by offering stability without adding excessive weight. Their ability to be customized in size and color makes them an attractive choice for various construction needs, enhancing both functionality and aesthetics. Whether for packaging or construction, PP hollow corrugated sheets prove to be a reliable and efficient resource.

Related Posts

-

7 Reasons Why Best Pp Hollow Corrugated Sheet is the Ultimate Choice for Your Business

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

Exceptional Manufacturing of Best Corrugated Plastic from China Serving the Global Market

-

What is the Best PP Corrugated Sheet and Why You Should Use It

-

Unlocking Advantages of Best Corrugated Plastic for Your Business

-

Unlocking Quality: Your Guide to Sourcing the Best Plastic Corrugated Sheets from Reliable Suppliers