- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Right Pp Corrugated Box for Your Needs?

Choosing the right PP corrugated box can make a significant difference in your packaging needs. According to a recent industry report by Smithers Pira, the demand for corrugated boxes is projected to reach $265 billion by 2024. This figure highlights the importance of selecting suitable materials for efficiency and cost-effectiveness.

PP corrugated boxes are known for their durability and light weight. Research indicates that these boxes can reduce shipping costs by up to 20%. They are also waterproof and resistant to various chemicals, making them ideal for industrial applications. However, not all PP corrugated boxes are created equal. You may encounter variations in quality, thickness, and design that can impact their performance.

While considering your options, think about the specific requirements of your products. How much weight can the box hold? Is it suitable for outdoor storage? Reflecting on these questions can help you avoid common pitfalls. Ultimately, investing time in selecting the right PP corrugated box can enhance your packaging strategy.

Understanding the Basics of PP Corrugated Boxes

PP corrugated boxes are becoming increasingly popular due to their lightweight and durable nature. These boxes are made from polypropylene, a type of plastic that offers excellent resistance to moisture and chemicals. According to a report by Smithers Pira, the demand for plastic packaging is projected to grow by 4% annually, indicating a positive trend for corrugated materials. Understanding these basics helps in making informed choices.

When selecting a PP corrugated box, consider its structure. Some boxes are single-wall, while others have multiple layers. Single-wall boxes are lighter but may not hold up under heavy loads. Multi-wall boxes offer increased strength and protection but can be bulkier. The right choice depends on your specific shipping or storage needs. An ideal approach is to assess the weight and fragility of the items being packaged.

Industry data reveals that 70% of packaging failures are due to improper box selection. This highlights the need for careful consideration. Not all PP corrugated boxes are created equal. Variations in thickness and design can greatly impact durability. Taking time for reflection on specific requirements can save costs and reduce waste. It’s essential to balance strength, weight, and cost effectively.

Understanding the Basics of PP Corrugated Boxes - Usage Distribution

Evaluating Your Packaging Needs and Requirements

When evaluating your packaging needs, consider the specific products you will be shipping. The weight, size, and fragility of items play a crucial role in choosing the right pp corrugated box. A sturdy box is essential for heavy products. For delicate items, padding may be necessary too. Think about the dimensions you require. A box that is too large can lead to movement during transit. This might damage the products inside.

Next, assess the environmental impact. Many packaging options exist, but not all are eco-friendly. Explore recyclable and reusable materials. While some might be cheaper, they may not suit your values. Consider how you want your brand perceived. This can influence packaging decisions.

Lastly, reflect on your budget and the quantity of boxes needed. Bulk orders might seem cost-effective. However, ensure you are not compromising on quality. Weigh both cost and reliability. A low-cost box might fail under pressure. This could lead to losses or dissatisfaction. Testing your choices before making a large order can save you from potential regret.

How to Choose the Right Pp Corrugated Box for Your Needs? - Evaluating Your Packaging Needs and Requirements

| Dimension | Material Type | Weight Capacity | Application | Closure Type |

|---|---|---|---|---|

| 12 x 10 x 8 in | Single Wall | 25 lbs | E-commerce Shipping | Foldable |

| 16 x 14 x 12 in | Double Wall | 50 lbs | Retail Products | Tape Sealed |

| 10 x 10 x 10 in | Single Wall | 20 lbs | Gift Packaging | Tab Lock |

| 24 x 18 x 16 in | Triple Wall | 70 lbs | Industrial Use | Strapped |

| 14 x 12 x 10 in | Single Wall | 30 lbs | Food Packaging | Peel & Seal |

Key Features to Consider When Selecting PP Corrugated Boxes

When selecting PP corrugated boxes, several key features warrant careful consideration. Size is crucial. Assess the dimensions of the items you intend to package. A box that is too large may lead to movement and damage. Conversely, a box that is too small could crush your products. Aim for a snug fit to prevent unnecessary shifting.

Durability is another vital aspect. PP corrugated boxes are designed to withstand rough handling. Check the thickness of the material. Thicker walls provide better protection. Examine the box's load capacity as well. It is essential to ensure that it can safely hold the weight of your products. Look for boxes with a solid structure, as some might bend or break under pressure.

Additionally, consider resistance features. Some PP boxes are water-resistant, making them suitable for various environments. Evaluate whether this is important for your specific needs. Price is a factor too, but it’s necessary to balance cost with quality. A cheaper box may not fulfill your requirements and may lead to additional costs in the long run. Reflect on these aspects before making a decision.

Comparing Different Types of PP Corrugated Boxes

When choosing PP corrugated boxes, it’s crucial to understand the different types available. These boxes vary in thickness, strength, and design, each catering to specific needs. For light items, a thinner box might suffice. However, heavier products require sturdier options. The thickness often ranges from 3mm to 7mm. This impacts durability and cost.

Consider the box design as well. Some boxes come with pre-assembled features, while others need assembly. Pre-assembled boxes save time but may not fit all item shapes. Customized designs can improve security but can also lead to increased expenses. There’s a balancing act between functionality and budget.

Another interesting aspect is the environmental impact. Many PP corrugated boxes are recyclable. However, not all recycling facilities accept them. This may lead to waste issues. Evaluating your local recycling options is essential. Reflecting on these factors can help in making a more informed decision.

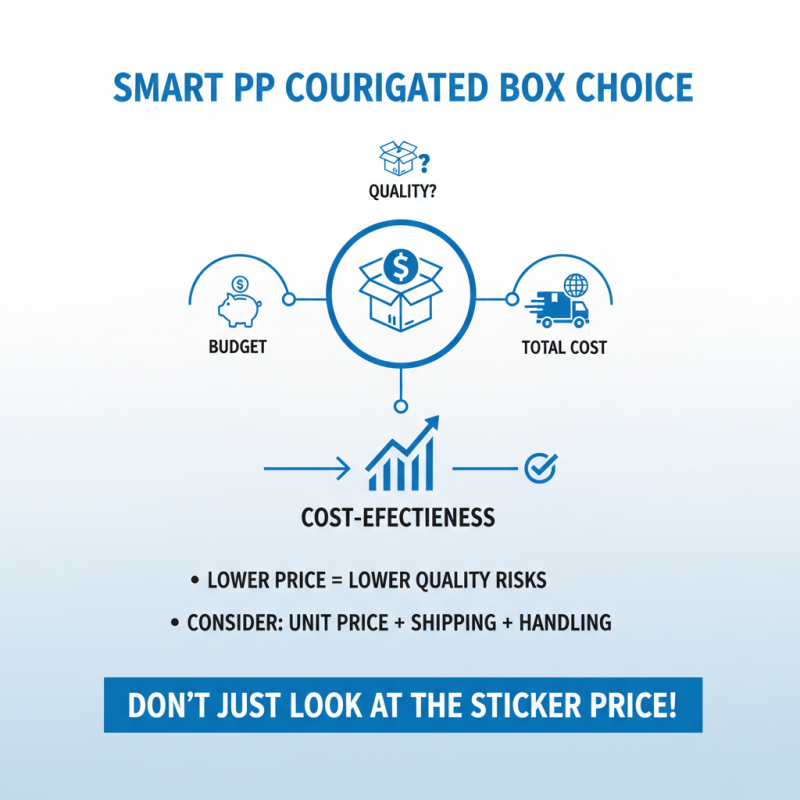

Assessing Cost-Effectiveness and Supplier Options

When it comes to selecting the right PP corrugated box, cost-effectiveness is key. Consider your budget while making a choice. Some suppliers may offer lower prices but skimp on quality. This can lead to issues like breakage and damage during transport. Assess the total cost, including shipping and handling. Don't just look at the sticker price.

Tips: Always request samples before placing a large order. This helps you evaluate the box's sturdiness. Check if the supplier has a return policy on defective boxes. It's a safeguard for unexpected problems.

Supplier options can vary significantly. Research different suppliers in your area. Look for reviews and success stories. A well-reviewed supplier may cost more but provides peace of mind. Beware of suppliers that seem too good to be true. They often compromise quality for a lower price. Remember, cheap can lead to high costs later on.

Tips: Create a checklist of your requirements. This will help in comparing different suppliers. Highlight features like size, weight capacity, and customizability. Keep your options open but stay focused on quality over price.

Related Posts

-

How to Choose the Best Pp Corrugated Box for Your Packaging Needs

-

Exploring the Surge in Pp Corrugated Box Demand at the Successful 137th Canton Fair

-

What is a Pp Corrugated Plastic Box and Why is it Your Best Packaging Solution?

-

Exploring the Impact of Pp Corrugated Sheet Innovations at the 138th Canton Fair 2025 in China

-

Exploring the Future of Pp Corrugated Boxes at China Import and Export Fair 2025: Trends and Opportunities

-

What is Pp Corrugated Box and Why It Dominates the Packaging Industry Trends