- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Best Corrugated Protection Sheet for Your Needs?

Choosing the right Corrugated Protection Sheet can feel overwhelming. With various types available, how do you decide? This guide aims to simplify the process.

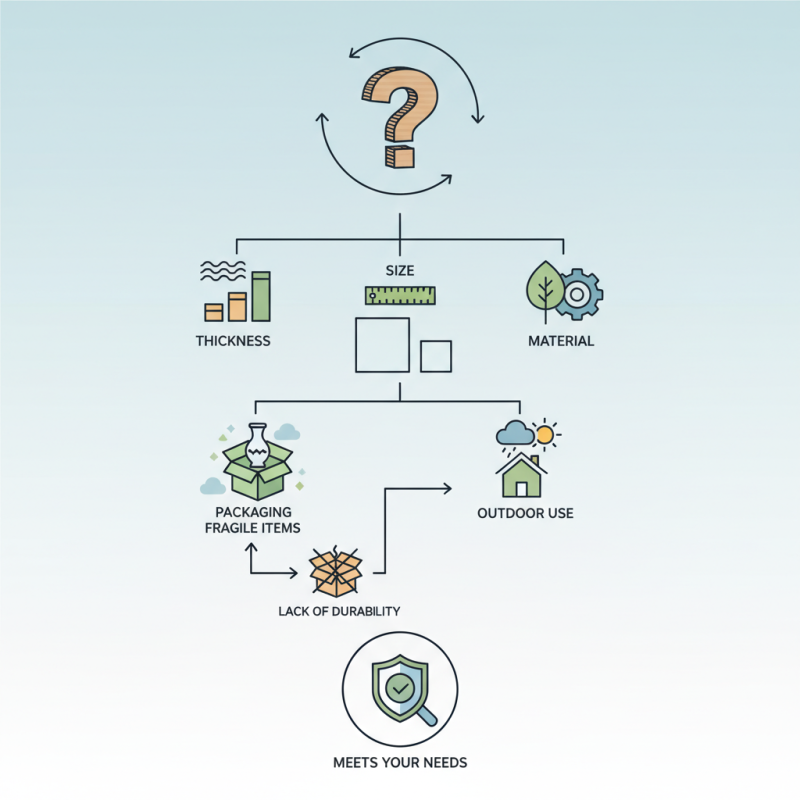

Consider factors like thickness, size, and material. Each choice can impact your protection needs. Corrugated sheets provide excellent cushioning and support. However, not all sheets fit every situation. Sometimes, you may pick a sheet that seems perfect but lacks necessary durability.

Understanding your unique requirements is key. Do you need it for packaging fragile items or outdoor use? Each scenario demands different qualities. Pay attention to these details. A small oversight could lead to damage. Reflect on past experiences to avoid mistakes. The goal is to find a Corrugated Protection Sheet that truly meets your needs.

Understanding Corrugated Protection Sheets and Their Applications

Corrugated protection sheets are essential in various industries. These sheets provide safety for products during storage and transport. They are lightweight, strong, and versatile. In construction, for example, they protect surfaces from scratches and impacts. In logistics, they help shield items from moisture and dust. Reports show that the global market for corrugated products is expected to grow by over 4% annually.

Choosing the right sheet involves understanding your specific needs. Different thicknesses and finishes cater to distinct applications. For fragile items, opt for thicker sheets. For standard packaging, standard thickness might suffice. Always consider the environmental impact. Some sheets are recyclable, which aligns with sustainability goals.

Tips: Always test samples before large purchases. Consider the weight of items you'll protect. Keeping an eye on market trends helps in making informed decisions. The right materials can minimize waste and reduce costs. Be cautious of low-quality options; they can lead to more damage in the long run.

Comparative Analysis of Corrugated Protection Sheet Thickness

This bar chart illustrates the weight of different thickness levels of corrugated protection sheets. As the thickness increases, the weight per sheet also increases, indicating the material's strength and protective capabilities for various applications.

Assessing Your Specific Protection Needs and Environmental Factors

When selecting the right corrugated protection sheet, understanding your specific protection needs is crucial. Consider the environment where the sheet will be used. For instance, temperature fluctuations can influence material performance. A report from the International Journal of Materials Science highlights that temperature resistance affects the durability of protective sheets. Sheets exposed to extreme conditions may degrade faster than expected.

Assess the weight and impact resistance you require. Different applications demand different durability. For example, materials with higher thickness levels often provide better protection against heavy objects. According to recent industry data, sheets with a thickness of 3mm to 5mm offer considerable resistance to common impact scenarios. However, they might be heavier and bulkier, posing transportation challenges.

Don't overlook aesthetic and functional aspects, either. Color options can enhance visibility and safety. Lightweight options may be easier to handle but can compromise strength. Thus, balancing weight and protection is a common dilemma. Industry experts suggest that selecting the appropriate sheet involves careful evaluation of all these factors. Emphasize your needs, but be prepared for trade-offs that may arise in the decision-making process.

Key Features and Specifications to Consider in Corrugated Sheets

When selecting a corrugated protection sheet, you must consider several key features. Material thickness is important. Thicker sheets offer better protection for items. However, they are heavier. Lighter sheets are easier to handle but may not provide sufficient support for fragile products.

Next, consider the type of corrugation. Single-wall sheets are suitable for light-duty needs. Double-wall sheets provide enhanced durability and are better for heavy or delicate items. Each type has its place in various applications. Think about how you will use the sheets.

Tips: Always check the weight capacity before purchasing. Ensure the sheet meets your specific requirements. Also, review the environmental impact of the materials you choose. Many buyers overlook this aspect, yet it is crucial for sustainability.

The size of the sheets matters too. Custom sizes can be beneficial, but they may lead to waste if not measured correctly. Cutting standard sheets can be tricky. Misjudgments can leave you with unusable scraps.

Comparing Different Materials and Types of Corrugated Protection Sheets

When selecting corrugated protection sheets, material choice is crucial. Common options include polypropylene, polycarbonate, and cardboard. Each material has distinct features that affect durability and cost. Polypropylene sheets are lightweight and resistant to chemicals. They work well for diverse applications. Polycarbonate, on the other hand, offers enhanced impact resistance. This makes it ideal for high-stress environments. Cardboard sheets are biodegradable but less durable, making them suitable for short-term use.

You should also consider the thickness and size of the sheets. Thicker sheets provide better protection against physical damage. However, they can be heavier and harder to handle. The size should match your specific needs. Using sheets that are too large or small can lead to inefficiencies. Reflecting on your needs is essential. Is the protection temporary or long-term? Can you handle the weight of thicker materials? These questions will guide your choice.

Remember, choosing the right material starts with understanding your requirements. Think about how you’ll use the sheets. Examine the environments they’ll face. It’s easy to overlook these nuances, but doing so could mean the difference between effective protection and failure. Stay focused on your application and the environment to find the optimal solution.

Evaluating Cost and Durability for Long-Term Usage Options

When selecting a corrugated protection sheet, cost and durability are two key factors. Consider the material's longevity. Some options appear cheaper upfront but may wear out quickly, leading to higher replacement costs. A more durable sheet might be a larger initial investment, but it can save money in the long run. Factor in the environments where the sheet will be used. Harsh conditions can wear down materials faster than anticipated.

Evaluate the thickness of the corrugated sheet. Thicker sheets often provide better protection but can be more expensive. Understand the implications of this choice. It may lead to over-spending if the extra durability isn't necessary for your situation. A balance between cost and necessary protection is crucial. Check the warranty length as well. A longer warranty often signifies confidence in the product's durability.

Reflect on your specific needs. Will the sheet face constant wear or harsh conditions? If so, prioritize durability over a lower price. Seeking feedback from users can provide insight into the performance of different materials. Keep in mind, not all products perform as advertised. Make an informed decision based on careful consideration.

How to Choose the Best Corrugated Protection Sheet for Your Needs?

| Material Type | Thickness (mm) | Durability (years) | Cost per Sheet ($) | Best Use Cases |

|---|---|---|---|---|

| Polypropylene | 4 | 5 | 25 | Temporary protection during shipping |

| High-Density Polyethylene (HDPE) | 6 | 10 | 30 | Long-term outdoor usage |

| Corrugated Cardboard | 5 | 2 | 10 | Temporary indoor protection |

| Polyethylene Terephthalate (PET) | 3 | 7 | 20 | Chemical-resistant applications |

| Expanded Polypropylene (EPP) | 8 | 15 | 50 | High-impact protection in automotive applications |

Related Posts

-

Why You Should Invest in Corrugated Protection Sheets for Your Business

-

2026 Best White Corrugated Sign Board Uses and Benefits?

-

How to Choose the Right Corrugated Plastic Board for Your Business Needs

-

Innovative Chinese Factory Delivering Premium Colored Corrugated Plastic Solutions for Global Buyers

-

Discovering Quality Suppliers for Best White Corrugated Sign Boards Effective Strategies for Global Buyers

-

Unlocking Quality: Your Guide to Sourcing the Best Plastic Corrugated Sheets from Reliable Suppliers