- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Right Corrugated Plastic for Your Business Needs: Insights and Industry Statistics

In today's competitive market, selecting the appropriate materials for your business operations is crucial, and corrugated plastic has emerged as a versatile choice for various industries. According to a recent industry report, the global corrugated plastic market is projected to reach $14 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2% from 2020. This growth is driven by the material's lightweight, durability, and recyclability, making it an ideal option for packaging, signage, and construction applications. As businesses increasingly prioritize sustainability, understanding the specific benefits and applications of corrugated plastic becomes essential. This article will guide you through the decisive factors to consider when choosing the right corrugated plastic for your business needs, supported by insights and statistics that underscore its value in the modern marketplace.

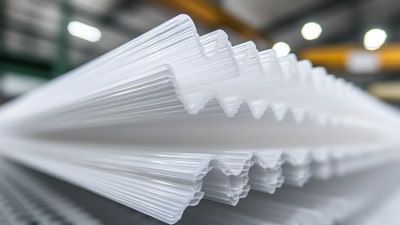

Understanding Different Types of Corrugated Plastic and Their Applications

When choosing the right corrugated plastic for business needs, understanding the different types and their applications is essential. Corrugated plastics, which come in various thicknesses and compositions, serve a wide range of purposes, from packaging and shipping materials to protective coverings for equipment. Key types include twin-wall and multi-wall designs, which provide varying levels of strength and insulation. Businesses must assess their specific requirements, such as durability, weather resistance, and sustainability considerations, to select the most appropriate type.

With increasing awareness of plastic pollution, the industry is witnessing a shift towards sustainable alternatives. The global corrugated plastic sheets market is projected to grow significantly, spurred by rising demand for lightweight and recyclable packaging solutions. Furthermore, innovations in bioplastics present promising alternatives that reduce environmental impact while maintaining necessary performance characteristics for applications like food packaging.

Understanding these dynamics can help businesses make informed choices that align with both operational needs and environmental responsibilities.

Key Industry Statistics on Corrugated Plastic Usage and Market Trends

The use of corrugated plastic has seen considerable growth across various industries, driven by its versatility and durability. According to recent statistics, the corrugated plastic market is projected to reach a valuation of over $5 billion by 2025, reflecting an annual growth rate of around 4.7%. This increase is largely attributed to its applications in packaging, construction, and advertising sectors, where businesses favor lightweight and weather-resistant materials. The shift towards eco-friendly products is also influencing market trends, as manufacturers are increasingly producing recyclable and reusable corrugated plastic options.

Furthermore, industry insights reveal that North America is currently one of the largest consumers of corrugated plastic, accounting for approximately 35% of the global market share. The rising demand for innovative packaging solutions, especially in e-commerce and retail, has significantly contributed to this trend. Additionally, advancements in manufacturing technologies are enabling the production of more complex designs and higher-quality materials, catering to the evolving needs of businesses. This combination of technological innovation and sustainability in production processes positions corrugated plastic as a key component in future market growth.

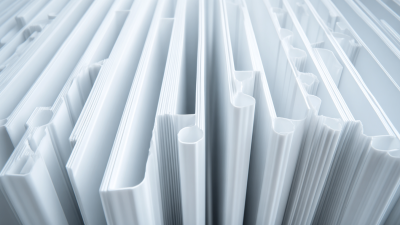

Factors to Consider When Selecting Corrugated Plastic for Your Business

When selecting corrugated plastic for your business needs, several key factors come into play. First, consider the thickness and durability of the material. Thicker sheets often provide greater strength and resistance to impact, making them suitable for applications that require longevity, such as outdoor signage or packaging. On the other hand, lighter options might be ideal for temporary displays or projects where portability is essential.

Another important consideration is the intended application of the corrugated plastic. Different industries may have specific requirements, such as moisture resistance for agricultural uses or UV stability for advertising in sunny locations. Additionally, you should evaluate the printing compatibility of the material if you plan to customize it with graphics. Finally, cost efficiency is vital; analyzing bulk purchasing options can lead to significant savings, ensuring you select the right balance between quality and price for your business objectives.

Evaluating Cost-Effectiveness: Comparing Corrugated Plastic with Other Materials

When evaluating the cost-effectiveness of corrugated plastic compared to other materials, businesses will find compelling statistics that highlight its advantages. According to a report by Grand View Research, the global corrugated plastic market is expected to grow significantly, projected to reach USD 6.83 billion by 2025, reflecting a keen interest in its utility across various industries. Notably, corrugated plastic is not only lightweight but also durable, translating to reduced shipping costs and lower handling fees for companies. This cost efficiency positions it favourably against traditional materials like wood and metal, which can be more expensive both in terms of initial investment and long-term maintenance.

Additionally, a study published by Smithers Pira highlights that corrugated plastic exhibits superior resistance to weather and chemicals when compared to paper-based options. This durability can lead to longer usage life, ultimately decreasing the overall cost per unit over time. With a return on investment (ROI) that often surpasses materials like cardboard—due to its reusability and recyclability—businesses can make informed choices that align with both budget constraints and sustainability goals.

Sustainability in Corrugated Plastics: Eco-Friendly Options and Certifications

Sustainability is becoming an increasingly vital consideration in the selection of materials, especially for businesses relying on packaging solutions such as corrugated plastics. According to a 2022 report by Smithers Pira, the global market for sustainable packaging is projected to reach $500 billion by 2025, with a significant segment driven by eco-friendly materials like corrugated plastics. These products, often made from recyclable and reusable resins, not only reduce environmental impact but also improve a company’s brand image in an eco-conscious market.

Moreover, various certifications exist to ensure that corrugated plastic products meet sustainability standards. The International Organization for Standardization (ISO) has established guidelines that help manufacturers adhere to environmental management practices. In a survey by the Sustainable Packaging Coalition, over 70% of respondents indicated that they prefer packaging suppliers who can provide verified sustainability certifications. As businesses aim to enhance their eco-friendly credentials, selecting corrugated plastics that align with these standards not only supports environmental goals but can also attract a growing customer base increasingly concerned with sustainability.

How to Choose the Right Corrugated Plastic for Your Business Needs: Insights and Industry Statistics - Sustainability in Corrugated Plastics: Eco-Friendly Options and Certifications

| Dimension | Material Type | Weight (lbs) | Thickness (mm) | Recyclability |

|---|---|---|---|---|

| 24" x 36" | Polypropylene | 1.5 | 4 | Yes |

| 36" x 48" | HDPE | 2.0 | 5 | Yes |

| 48" x 96" | PVC | 3.5 | 6 | No |

| 60" x 120" | Recycled Polypropylene | 4.2 | 7 | Yes |

Related Posts

-

Exceptional Manufacturing of Best Corrugated Plastic from China Serving the Global Market

-

Unlocking Advantages of Best Corrugated Plastic for Your Business

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

The Future of Sustainable Solutions with Best White Corrugated Plastic

-

7 Best Benefits of Using Corrugated Plastic Rolls in Global Packaging Solutions

-

Ultimate Guide to Choosing the Right Corrugated Plastic Rolls for Your Business Needs