- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Right Corrugated Plastic Rolls for Your Projects?

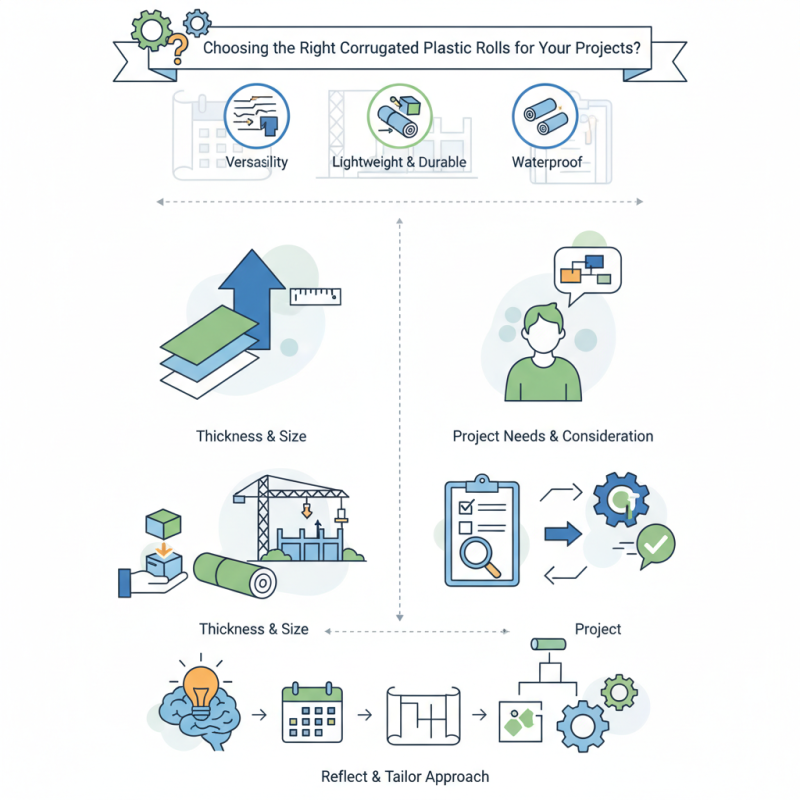

Choosing the right Corrugated Plastic Rolls can significantly impact your projects. These versatile materials offer numerous applications. They are lightweight, durable, and waterproof, making them suitable for outdoor use.

When selecting Corrugated Plastic Rolls, consider the thickness and size. Thicker rolls provide better stability. Smaller sizes are handy for confined spaces. However, remember that the right choice depends on your specific project needs.

It can be overwhelming with so many options available. You might find yourself uncertain about which features matter most. Don't rush the decision. Take time to reflect on your project requirements and how Corrugated Plastic Rolls can fulfill them. Each project is unique, and a tailored approach can lead to better results.

Understanding Corrugated Plastic Rolls and Their Applications

Corrugated plastic rolls are versatile materials used in various industries. They are lightweight, durable, and water-resistant. The applications for these rolls include signage, packaging, and temporary structures. Reports indicate that the global market for corrugated plastic is growing. By 2026, the market is projected to surpass $1 billion, driven by demand from multiple sectors.

When considering the right type of corrugated plastic for your project, think about its thickness and density. Thicker options offer greater strength but may be heavier and less flexible. For example, 4mm corrugated plastic is popular for outdoor signs, while 2mm is ideal for indoor displays. However, not all projects require heavy-duty materials.

Understanding specific applications is crucial. Some projects may benefit from UV protection, while others need only basic water resistance. It’s worth noting that environmental concerns arise. Many corrugated plastics are not biodegradable. Recycling options are limited, leading to waste. Industries should reflect on sustainability when selecting materials.

Factors to Consider When Choosing Corrugated Plastic Rolls

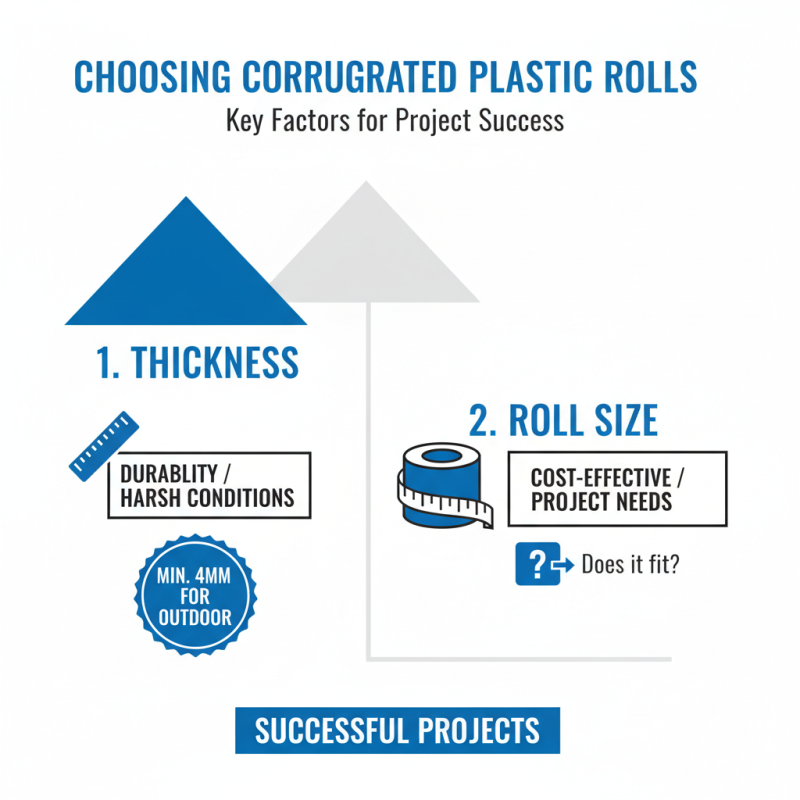

Choosing the right corrugated plastic rolls can significantly impact the success of your projects. Several key factors influence your decision. First, consider thickness. Thicker materials often provide better durability and can withstand harsh conditions. Most industry reports suggest a minimum thickness of 4mm for outdoor use. Also, check the roll size. Bigger rolls can be cost-effective, but make sure they fit your project needs.

Another essential factor is the color and finish. Light colors reflect heat, reducing temperature during hot weather. Darker colors absorb heat, which might be beneficial in cooler climates. A report from the Flexographic Technical Association indicates that color can affect product lifespan. Be cautious; it may seem trivial, but the right color can make a significant difference.

Tips: Always test a small section before committing to large quantities. It can save time and reduce waste. Remember, not all rolls are created equal. Some may have inconsistencies in strength, which could lead to project failure. Assess your requirements thoroughly. Keep a checklist handy to ensure you don't overlook critical aspects while selecting your rolls.

Evaluating Thickness and Durability for Your Project Needs

When choosing corrugated plastic rolls, evaluating thickness and durability is crucial. Thickness typically ranges from 2 mm to 10 mm. Thicker materials provide better rigidity and strength. However, they may also add weight and cost.

Durability plays a vital role in project performance. Projects exposed to harsh environments require robust materials. A study by the Plastics Industry Association indicates that corrugated plastic can endure extreme temperatures and resist moisture and chemicals. This means your choice can significantly influence the longevity of your project.

Tips: Consider the project’s location and exposure to elements. If stability is key, opt for thicker rolls. Test samples before the final decision. Assess how they withstand bending and impacts; this could reveal weaknesses.

Weight is another factor to ponder. Thicker rolls may not be practical for all applications. A heavy roll can complicate handling. Balancing thickness with usability is essential. Being mindful of your specific needs will ensure the best results.

Types of Corrugated Plastic Rolls Available on the Market

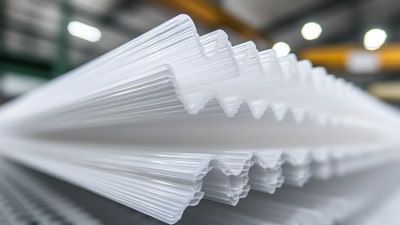

When choosing corrugated plastic rolls, understanding the types available is crucial. Corrugated plastic rolls come in various forms. These include standard twin-wall sheets, which are lightweight and versatile. These sheets provide excellent resistance to moisture and chemicals, making them suitable for outdoor use. The global demand for corrugated plastics has surged. According to recent industry reports, the market is projected to grow by 4.5% annually through 2027.

Another type is the fluted design, which is more rigid. This design offers enhanced strength for structural applications. Fluted sheets are used in signage and packaging. Their superior durability makes them ideal for longer-term projects. It's important to note that not all corrugated plastics are created equal. Some variations in thickness and density can significantly affect performance.

Transparency is also a factor. Clear corrugated plastic sheets allow light to pass through. This feature is beneficial for greenhouse applications or outdoor displays. Users should consider the environmental impact as well. Many corrugated plastics are recyclable, but the facilities available may vary. As choices expand, reflect on your specific needs. Do the options align with your project requirements?

How to Choose the Right Corrugated Plastic Rolls for Your Projects? - Types of Corrugated Plastic Rolls Available on the Market

| Type of Corrugated Plastic | Thickness (mm) | Common Uses | Color Options | Weight (kg/m²) |

|---|---|---|---|---|

| Standard Corrugated Plastic | 3 | Signage, Displays | White, Yellow, Blue | 0.5 |

| Heavy-Duty Corrugated Plastic | 5 | Packaging, Construction | Black, Green, Red | 0.8 |

| Flame-Retardant Corrugated Plastic | 4 | Safety Signs, Industrial Use | White, Gray | 0.6 |

| Transparent Corrugated Plastic | 3 | Greenhouses, Light Diffusion | Clear | 0.5 |

| Custom Printed Corrugated Plastic | 3-5 | Advertising, Branding | Custom Colors | 0.6-0.8 |

Cost-Effectiveness and Sourcing Options for Corrugated Plastic Rolls

When considering corrugated plastic rolls for your projects, cost-effectiveness is key. According to industry reports, these materials can significantly reduce overall project costs compared to alternatives like cardboard or foam. In fact, the average price of corrugated plastic rolls is often about 25% lower than traditional options. This makes them appealing for both short-term and long-term applications.

Sourcing options vary widely, impacting final cost. Bulk purchases usually provide better pricing. Suppliers often offer discounts for larger orders. Additionally, looking into local manufacturers can save on shipping costs. The transportation factor plays a critical role. Some businesses found that local sourcing decreased expenses by up to 15%. Yet, sourcing locally might limit material variety.

Recycling potential is another consideration. Many manufacturers promote their products' recyclability. However, not all options are created equal. Some corrugated plastics are more challenging to recycle than others. Companies must weigh the environmental costs against the upfront savings. Buyers should evaluate both factors carefully to ensure a truly cost-effective choice.

Cost-Effectiveness of Corrugated Plastic Rolls

Related Posts

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

Yellow Corrugated Plastic Uses and Tips for Effective Applications?

-

How to Use Corrugated Plastic for Versatile Applications?

-

The Future of Sustainable Solutions with Best White Corrugated Plastic

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success

-

10 Best Uses of White Corrugated Plastic for Your Projects?