- export5@runpingpp.com

- 24 Hours Online

Industry News

How to Choose the Right Pp Corrugated Sheet for Your Business Needs

Selecting the appropriate PP corrugated sheet is crucial for businesses looking to enhance their operational efficiency and product durability. According to a report by Smithers Pira, the global demand for lightweight packaging materials, including PP corrugated sheets, is projected to reach $350 billion by 2024, as companies increasingly prioritize sustainability and cost-effectiveness.

PP corrugated sheets are renowned for their excellent strength-to-weight ratio and moisture resistance, making them suitable for various applications such as protective packaging, advertising displays, and industrial uses. Understanding the specific requirements of your business, including factors like thickness, density, and environmental impact, is vital for making an informed decision. In this guide, we will explore the key considerations and industry standards to help you choose the right PP corrugated sheet tailored to your business needs, ensuring optimal performance and value.

PP corrugated sheets are renowned for their excellent strength-to-weight ratio and moisture resistance, making them suitable for various applications such as protective packaging, advertising displays, and industrial uses. Understanding the specific requirements of your business, including factors like thickness, density, and environmental impact, is vital for making an informed decision. In this guide, we will explore the key considerations and industry standards to help you choose the right PP corrugated sheet tailored to your business needs, ensuring optimal performance and value.

Identifying Your Business Requirements for PP Corrugated Sheets

When selecting the right PP corrugated sheets for your business, it is essential to start by identifying your specific requirements. Consider the purpose of the sheets—will they be used for packaging, signage, or as structural components? This understanding will guide you in choosing the appropriate thickness, strength, and surface treatment necessary for your applications.

Tips: Start by evaluating the weight and type of items you intend to package or protect. For heavier goods, opt for thicker sheets that offer increased durability. Additionally, think about the environmental conditions your sheets will face, such as exposure to moisture or extreme temperatures, which can influence the material's performance.

Another crucial factor is the aesthetic appeal of the PP corrugated sheets. If your business relies on visual branding, selecting sheets that can be easily printed or colored may be beneficial. Assess whether your sheets need additional features like UV resistance or anti-static properties based on your industry needs.

Tips: Always check with suppliers for customization options. Many manufacturers offer tailored solutions that can enhance your product’s visibility and functionality, ensuring that you get the best value for your investment.

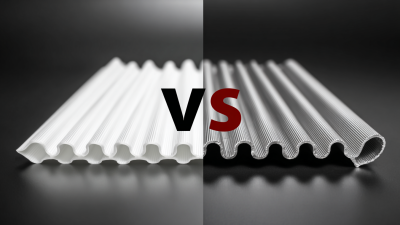

Understanding Different Types of PP Corrugated Sheets Available

When choosing the right PP corrugated sheet for your business, it’s crucial to understand the different types available. The most common type is the twin-wall PP corrugated sheet, which offers a good balance of strength and weight. This type is versatile and can be used for packaging, displays, and even temporary walls due to its durability. The twin-wall structure consists of two sheets bonded together, providing enhanced rigidity and resistance to impact.

Another important variation is the single-wall PP corrugated sheet, which is lighter and typically used for applications requiring less structural support. Ideal for lightweight packaging solutions, this sheet is easier to handle and can be printed on, making it an attractive choice for branding. Additionally, there are specialty PP corrugated sheets, such as those with UV protection, which are designed to withstand prolonged exposure to sunlight. Understanding these options allows businesses to select the right type of sheet that best meets their specific operational needs.

How to Choose the Right PP Corrugated Sheet for Your Business Needs

| Type | Thickness (mm) | Weight (kg/m²) | Durability | Common Applications |

|---|---|---|---|---|

| Standard PP Corrugated Sheets | 2.5 | 2.5 | Moderate | Packaging, Signage |

| Heavy Duty PP Corrugated Sheets | 5.0 | 5.0 | High | Industrial Packaging, Construction |

| E-Flute PP Corrugated Sheets | 3.5 | 3.0 | High | Display, Advertising Boards |

| UV-Resistant PP Corrugated Sheets | 4.0 | 4.0 | Very High | Outdoor Signage, Agricultural Use |

| Colored PP Corrugated Sheets | 2.0 | 2.0 | Moderate | Crafts, Decor |

Evaluating the Durability and Flexibility of PP Materials

When selecting the right PP corrugated sheet for your business, evaluating the durability and flexibility of the material is crucial. Polypropylene (PP) is known for its remarkable resistance to various environmental factors, including moisture and chemicals. This makes it an excellent choice for businesses that require robust packaging solutions. Furthermore, the flexibility of PP materials allows for easy manipulation and customization, which is essential for creating tailored products that meet specific business needs.

**Tips:** Consider the thickness of the PP corrugated sheets, as thicker options typically offer enhanced durability for heavy-duty applications. Additionally, look for sheets that have been treated for UV protection if your products will be exposed to sunlight, as this will ensure longevity and maintain structural integrity over time.

Another key factor is the weight-to-strength ratio of the PP sheets. Lightweight sheets can reduce shipping costs while still providing adequate strength for transportation and storage. You can also explore options like double-wall constructions for increased durability without the added weight. Always conduct a sample test to evaluate how well the material meets your specific requirements before committing to large orders.

Evaluating the Durability and Flexibility of PP Corrugated Sheets

Analyzing Cost-Effectiveness and Budget Considerations

When selecting the right PP corrugated sheet for your business, analyzing cost-effectiveness and budget considerations is crucial. The first step is to assess the overall project requirements, including the intended use of the sheets, the volume needed, and any specific features such as thickness or custom sizes. Understanding these parameters enables businesses to determine the most cost-efficient options that meet their operational needs without compromising quality.

Next, it’s essential to compare prices from different suppliers while considering the long-term value of the sheets. Some may offer lower initial costs but might lack durability or require frequent replacements, leading to hidden costs that affect the bottom line. Additionally, evaluate factors such as shipping expenses, lead times, and potential bulk discounts. By conducting a thorough cost analysis, businesses can make informed decisions, ensuring that their choice of PP corrugated sheets delivers both functionality and financial sustainability.

Choosing the Right Supplier for Quality PP Corrugated Sheets

When selecting a supplier for PP corrugated sheets, quality assurance is paramount. According to a recent report by Grand View Research, the global market for corrugated plastic sheets is expected to reach USD 3.11 billion by 2025, growing at a CAGR of 5.8%. This indicates a burgeoning demand for high-quality materials, making it crucial that businesses partner with suppliers that comply with industry standards. Look for suppliers who provide certificates like ISO 9001, which ensures that they adhere to quality management principles throughout their production processes.

Moreover, consider the supplier’s track record in providing durable and reliable products. The strength and longevity of PP corrugated sheets can significantly impact your business operations. A study from Technavio highlights that superior-grade materials can result in up to a 20% reduction in costs associated with product failures and returns. Reach out to potential suppliers to request specifications, sample products, and customer testimonials. A reputable supplier will not only offer competitive pricing but also guarantee the quality, helping to ensure that your business meets its operational goals without compromising on durability.

Related Posts

-

Exploring the Surge in Pp Corrugated Box Demand at the Successful 137th Canton Fair

-

7 Reasons Best Corrugated Plastic Totes Are Revolutionizing Supply Chain Efficiency

-

Ultimate Checklist for Choosing the Best Corrugated PP Products for Your Business Needs

-

How to Choose the Best PP Corflute Sheet for Your Global Sourcing Needs

-

Ultimate Comparison: Why the Best Plastic Corrugated Sheet Stands Out Among Competitors

-

Crafted with Precision Premium Corrugated Plastic Box Manufacturing for Global Supply Chain Excellence