- export5@runpingpp.com

- 24 Hours Online

Industry News

What is Corrugated Plastic Board and Its Uses?

Corrugated Plastic Board is transforming various industries with its unique properties. This durable material is lightweight yet strong. According to a study by Smith Plastics Research, the market for corrugated plastic is expected to grow by 5.6% annually. Notably, Dr. Lisa Tran, a leading expert in the field, states, "The versatility of corrugated plastic opens up endless possibilities for innovative applications."

From signage to packaging, its uses are manifold. In construction, it's used for temporary barriers and protective covers. In agriculture, it serves as an effective solution for plant protection. However, challenges remain in recycling these materials efficiently. Many users are unaware of the environmental impact. "We need to rethink the lifecycle of corrugated plastic," says Dr. Tran, emphasizing the importance of sustainable practices.

Industry professionals are exploring innovations to address these issues. Integrating biodegradable options could enhance sustainability. Despite its benefits, reliance on corrugated plastic raises concerns about waste. Reflecting on these factors is essential for future developments. With proper awareness and action, the positive impact of Corrugated Plastic Board can be maximized.

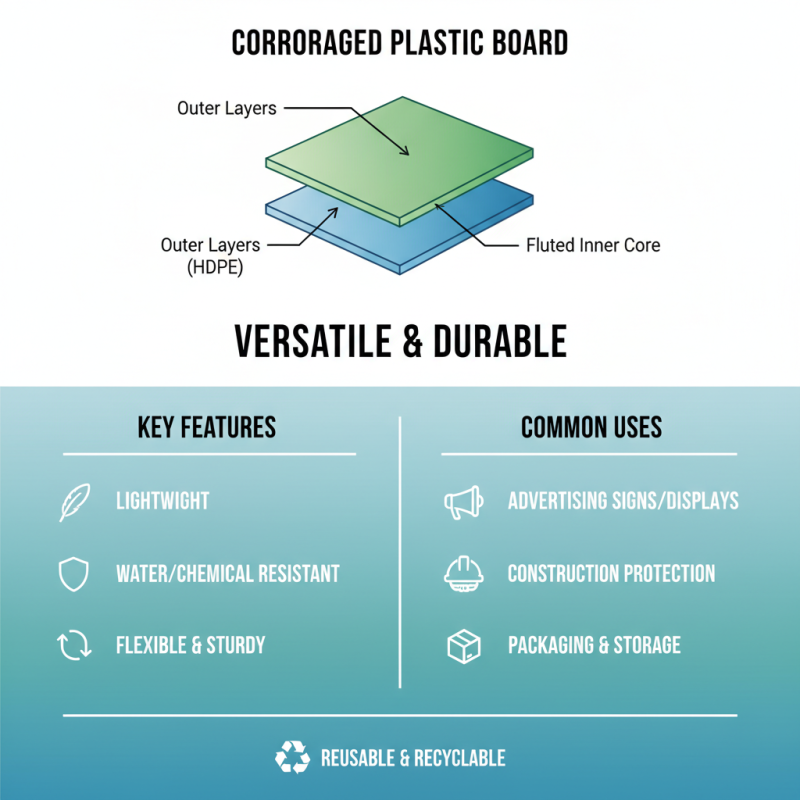

What is Corrugated Plastic Board?

Corrugated plastic board, often known for its lightweight and durable features, is a versatile material made from two outer layers of high-density polyethylene and a fluted inner layer. This construction makes it sturdy yet flexible, ideal for various applications. In industries ranging from advertising to construction, these boards serve numerous purposes. According to a recent market report, the global demand for corrugated plastics is expected to grow by approximately 5% annually.

In advertising, corrugated plastic boards are often used for yard signs and promotional displays. Their ability to withstand weather conditions makes them perfect for outdoor use. Additionally, schools and businesses utilize this material for temporary partitions and protective barriers. However, the environmental impact of this plastic should be considered. Many facilities struggle with recycling these products properly.

Tips: When using corrugated plastic boards, consider their size and weight. Light materials might not hold up in strong winds. Ensure to secure your signs properly. Additionally, look for suppliers who prioritize eco-friendly options. This approach can mitigate environmental concerns.

Overall, while its benefits are clear, reflect on the sustainability of your choices. The convenience of plastic can overshadow its long-term effects. Aim for a balanced perspective when selecting materials.

Composition and Manufacturing Process of Corrugated Plastic Boards

Corrugated plastic boards are increasingly popular due to their versatility. These boards are usually made of two flat sheets of plastic, typically polypropylene, with a fluted interior. This construction provides strength and durability while keeping the weight low. Reports indicate that the global demand for corrugated plastic has grown by 7% annually.

The manufacturing process involves several steps. First, the raw plastic is extruded into a sheet and shaped into a corrugated structure. Then, these sheets are cut to size for various applications. The entire process can be economized through recycling. Studies show that around 30% of the materials used in this process can come from recycled plastics.

Tips: When using corrugated plastic boards, ensure they are UV resistant if used outdoors. Consider integrating colors to enhance visibility for signage. Even small variations in thickness can affect performance, so it’s vital to choose the right specifications for your needs. The flexibility and lightweight nature can lead to some misconceptions about durability, so understanding the limitations is essential.

Common Uses of Corrugated Plastic Boards in Various Industries

Corrugated plastic board is a versatile material found in many industries. Its lightweight yet durable nature makes it ideal for use in signage, protective packaging, and construction. Most often, you will see it in real estate signs, political campaign materials, and event displays. The vibrant colors and easy customization draw attention and enhance visibility.

In the agricultural sector, corrugated plastic is used for plant protection and crop covers. It serves well as a weather-resistant shield. Moreover, it can be easily reused and recycled, making it a sustainable option. However, some industries might struggle with its disposal. The challenge of its environmental impact should not be overlooked.

Retailers also benefit from corrugated plastic. They use it for product displays and packaging, ensuring goods remain safe during transit. Despite its functionality, some businesses store it improperly, leading to unnecessary wear and tear. This oversight can diminish its lifespan and increase costs over time.

Common Uses of Corrugated Plastic Boards in Various Industries

Advantages of Using Corrugated Plastic Boards Over Other Materials

Corrugated plastic boards are gaining popularity in various industries. They are lightweight yet durable. This makes them ideal for temporary signs and displays. Their resistance to weather conditions is a notable advantage. Unlike cardboard, they don't easily get damaged by rain or sun. This makes them perfect for outdoor use.

In comparison to other materials, corrugated plastic boards offer unique benefits. They are often more cost-effective than wood or metal. Installation is quick and easy, requiring minimal tools. Moreover, these boards are recyclable, which aligns with eco-friendly practices. But there are considerations. They may not have the same aesthetic appeal as some other materials. For certain applications, this could be a drawback. Additionally, if not properly secured, they can shift in windy conditions.

Overall, the versatility of corrugated plastic boards is clear. They are used in advertising, construction, and packaging. However, potential users must weigh their pros and cons. Understanding the specific needs of a project is essential. Sometimes, other materials might serve better depending on the situation.

Environmental Impact and Recycling of Corrugated Plastic Boards

Corrugated plastic boards are versatile materials used in various applications. They are lightweight yet durable, making them popular for signage, packaging, and even construction. However, understanding their environmental impact is crucial.

The production of corrugated plastic boards involves the use of polymers, which come from non-renewable resources. This raises concerns about sustainability. While these boards are often reusable and recyclable, not all recycling facilities accept them. Many end up in landfills, neglecting their potential for repurposing.

Additionally, the recycling process itself can be inefficient. It is often complicated by contamination and the need for proper sorting. Education on disposal options is lacking. People may not realize that corrugated plastic can be recycled. So, while these boards serve practical purposes, their environmental footprint cannot be overlooked. Awareness and innovation are needed to improve their lifecycle.

What is Corrugated Plastic Board and Its Uses?

| Dimension | Description | Common Uses | Recycling Potential |

|---|---|---|---|

| 3mm | Lightweight and flexible, suitable for various applications. | Signage, displays, temporary walls. | Fully recyclable; repurposed into new boards. |

| 5mm | Durable and sturdy; maintains its shape under pressure. | Floor protection, crates, outdoor signs. | Can be recycled; often used in horticulture. |

| 10mm | Thicker, provides better insulation and soundproofing. | Construction site barriers, exhibition stalls. | Highly recyclable; suitable for multiple cycles. |

| Unique Prints | Customizable with various printing techniques. | Advertising, promotional displays. | Recycling often depends on print materials used. |

Related Posts

-

Ultimate Guide to Sourcing High Quality Plastic Corrugated Sheets for Diverse Applications

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success

-

2025 Guide: How to Choose the Best Plastic Corrugated Sheet for Your Project

-

Top Tips for Using Corrugated Plastic Rolls Effectively?

-

2026 Best Corrugated Plastic Uses and Benefits Explained?

-

Why Choose Corrugated Plastic Rolls for Your Next Project?