- export5@runpingpp.com

- 24 Hours Online

Industry News

Top Tips for Using Corrugated Plastic Rolls Effectively?

Corrugated Plastic Rolls are versatile materials widely used in various applications. These lightweight and durable sheets can serve multiple purposes, from signage to packaging. However, using them effectively requires understanding their unique features and limitations.

In many projects, people underestimate the importance of proper handling. For instance, cutting the rolls incorrectly can lead to wastage. Ensuring clean edges is crucial for a professional look. Additionally, improper storage may cause warping, making them less useful. It’s essential to pay attention to how they are stored and maintained.

When it comes to applications, flexibility is key. Corrugated Plastic Rolls can be used creatively, but it's equally easy to misuse them. Over-reliance on adhesive might fail, resulting in unwanted detachments. Balancing innovation with basic techniques can enhance your results. Achieving the best outcome often requires some trial and error. So, explore, adapt, and refine your approach to using Corrugated Plastic Rolls.

Understanding Corrugated Plastic Rolls and Their Applications

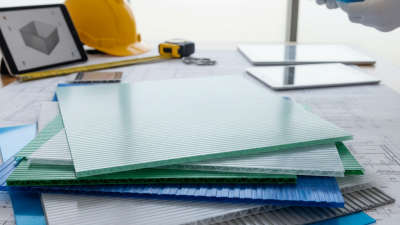

Corrugated plastic rolls are gaining popularity in various applications. Made from high-density polyethylene, they are lightweight and durable. According to a report by Smithers, the global market for corrugated plastics is projected to grow at a CAGR of 5.5% until 2025. This growth is driven by their versatility and cost-effectiveness.

These rolls are used in packaging, construction, and advertising. In packaging, they provide reliable protection for products during transportation. Their weather-resistant properties make them ideal for outdoor signs. A recent survey found that 68% of businesses prefer corrugated plastic for signage due to its longevity. However, not all uses are optimal; some users struggle with cutting and shaping the material. It's essential to have the right tools for precise customization.

While their benefits are clear, there are challenges. Some users report difficulties in recycling corrugated plastics. The lack of awareness about recycling options can lead to waste. Additionally, though they are water-resistant, prolonged exposure to UV light can degrade the material. Understanding these limitations better can enhance their effectiveness in various projects.

Usage of Corrugated Plastic Rolls in Various Applications

Choosing the Right Type of Corrugated Plastic for Your Project

When choosing corrugated plastic for your project, consider its specific characteristics. There are various types available, each suited for different applications. Polypropylene is lightweight and flexible. It works well for indoor signs, while high-density polyethylene offers more durability for outdoor use. Think about where your project will be placed.

Tips: Measure your space carefully. The right dimensions can prevent issues later on. Test small samples before committing to a large roll. You don’t want to find out it’s not suitable when it’s too late.

Also, pay attention to thickness. Thicker corrugated plastic holds up better against wind and rain. However, it can be bulkier and harder to handle. Make sure your project can accommodate the extra weight. Choosing the appropriate color can impact visibility, especially in bright environments.

Over time, you might discover that the plastic doesn’t hold up as expected. Reflecting on the usage environment can help you decide when to switch materials. Trial and error is part of the learning process.

Techniques for Cutting and Shaping Corrugated Plastic Rolls

Cutting and shaping corrugated plastic rolls can be challenging. These materials are versatile and used widely in various industries. However, improper techniques may lead to waste and frustration. Reports indicate that nearly 30% of materials are wasted due to poor cutting methods. Understanding proper techniques can greatly reduce this figure.

To start, ensuring clean, precise cuts is crucial. Use a sharp utility knife for straight cuts. Dull blades may crush the material, leading to uneven edges. For intricate shapes, consider using scissors, but be mindful of the thickness.

Many users overlook the importance of the cutting surface. A cutting mat or a flat, sturdy board prevents damage and maintains the integrity of the material.

Shaping is just as important as cutting. Heat can help bend corrugated plastic. A heat gun may soften the material, allowing for smoother curves. Be cautious, though; too much heat can warp or damage the sheet.

Some users have noted that achieving a consistent bend requires practice. Experimentation may lead to a better understanding of how to manipulate the material effectively.

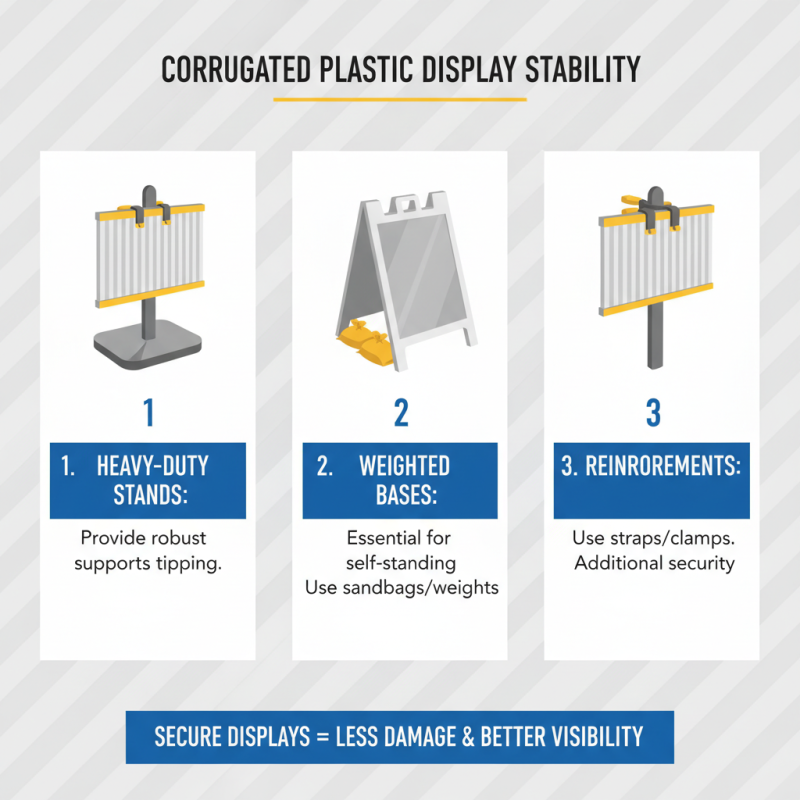

Best Practices for Displaying and Supporting Corrugated Plastic

When displaying corrugated plastic, stability is key. Using heavy-duty stands can help support your signs effectively. If you’re relying on self-standing displays, make sure they are weighted properly. Straps or clamps can provide additional reinforcement. A secure display prevents damage and enhances visibility.

Consider the environment where your displays will be used. Outdoors, wind can cause instability. You might want to create weights or anchors to hold your displays in place. Indoors, avoid overcrowded spaces. Ensure there’s enough room for your viewers. This clarity will make your message stand out.

Colors can affect visibility. Bold colors attract attention, but don’t overdo it. Too many colors may confuse your audience. Instead, stick to a coherent palette that aligns with your message. Lastly, remember to check your setups regularly. Over time, support materials can degrade. Regular maintenance ensures your displays remain effective and visually appealing. It’s a constant practice of reflection and improvement.

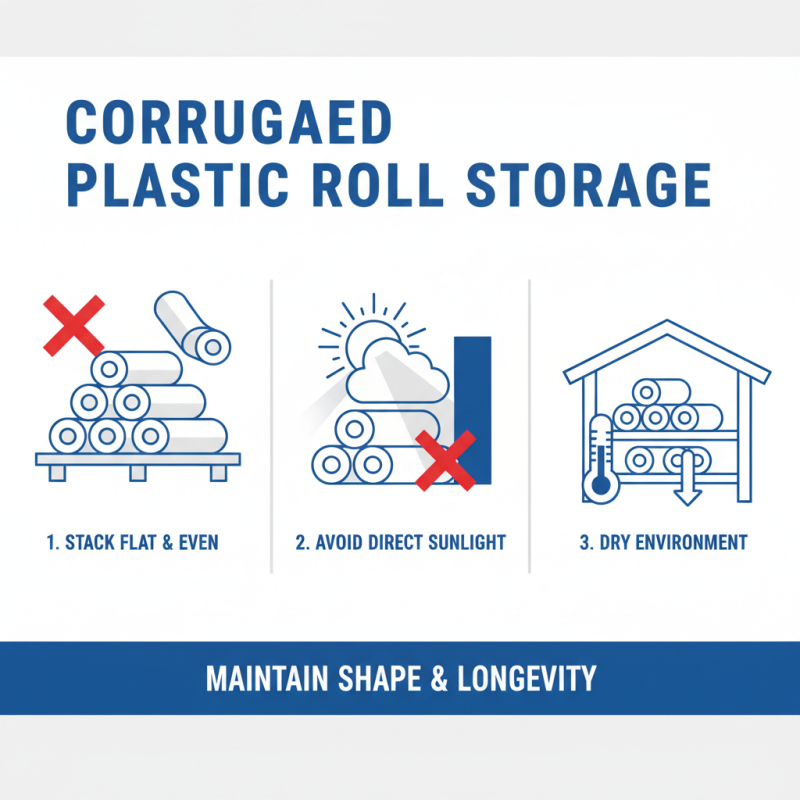

Maintaining and Storing Corrugated Plastic Rolls for Longevity

When it comes to keeping corrugated plastic rolls in top shape, proper storage is crucial. If you stack them carelessly, they can bend or warp. Choose a dry area, away from direct sunlight. Sunlight can cause degradation over time. Keep them on a flat surface, which helps maintain their structure.

Another tip is to clean the rolls before storing. Dust and debris can settle and cause issues later. Use a soft cloth or mild soap solution to wipe them down. Ensure they are completely dry before storing. This simple action extends their life significantly.

Sometimes, we forget to monitor the condition of these materials. Regularly check for any signs of damage or wear. If they’re not in good shape, fix them or get new ones. Maintaining an eye on your corrugated plastic rolls can save you time and money in the long run. Remember, a little care goes a long way.

Related Posts

-

7 Best Benefits of Using Corrugated Plastic Rolls in Global Packaging Solutions

-

2025 Guide: How to Choose the Best Plastic Corrugated Sheet for Your Project

-

Exploring the Benefits of Using White Corrugated Plastic for Your Business Needs

-

The Ultimate Guide to Understanding the Benefits of Plastic Corrugated Pads in Packaging Solutions

-

Unlocking Quality: Your Guide to Sourcing the Best Plastic Corrugated Sheets from Reliable Suppliers

-

Unlocking the Advantages of Using the Best Corrugated Plastic Rolls for Your Business Needs