- export5@runpingpp.com

- 24 Hours Online

Industry News

Top Tips for Using Corrugated Protection Sheets Effectively?

Using Corrugated Protection Sheets can greatly enhance the safety and durability of your products during transport and storage. These versatile sheets are designed to absorb shocks and protect items from scratches. They are lightweight yet sturdy, making them an ideal choice for various applications.

When it comes to utilizing Corrugated Protection Sheets effectively, there are best practices to consider. For instance, ensuring proper sizing can minimize waste and increase protection. It’s also crucial to evaluate the specific needs of your items, rather than assuming a one-size-fits-all approach. You might find that some products require extra layers, while others may not need as much shielding.

Remember, while these sheets provide a solid protective barrier, they may not solve every issue. Reevaluating your packaging strategies can lead to better outcomes. Being open to adjustments and improvements in your process is key to maximizing the benefits of using Corrugated Protection Sheets. Think about your current methods and identify opportunities for enhancement.

Understanding the Types of Corrugated Protection Sheets Available in the Market

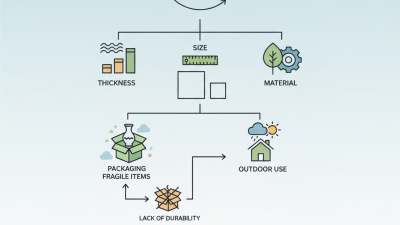

When exploring corrugated protection sheets, it's vital to understand the various types available. There are polycarbonate, cardboard, and polyethylene options on the market. Each type offers unique benefits. Polycarbonate sheets are strong and resistant to impact. Cardboard is eco-friendly and lightweight. Polyethylene is flexible and waterproof.

Consider the specific needs of your project. For outdoor use, polycarbonate might be suitable due to its durability. If you're looking for something temporary, cardboard can be a good choice. Remember, each type has its limitations too. For instance, cardboard can become soggy in rain. Weigh these factors before making a decision.

Tips for effective use can greatly enhance protection. Always ensure the sheets are cut to the correct dimensions. Wrapping them around products can provide extra cushioning. Using tape to secure edges helps maintain structure. Review your material choice regularly. Are you using the best type for your needs? This reflection can save time and enhance protection efficiency.

Assessing the Durability and Strength of Different Corrugated Materials

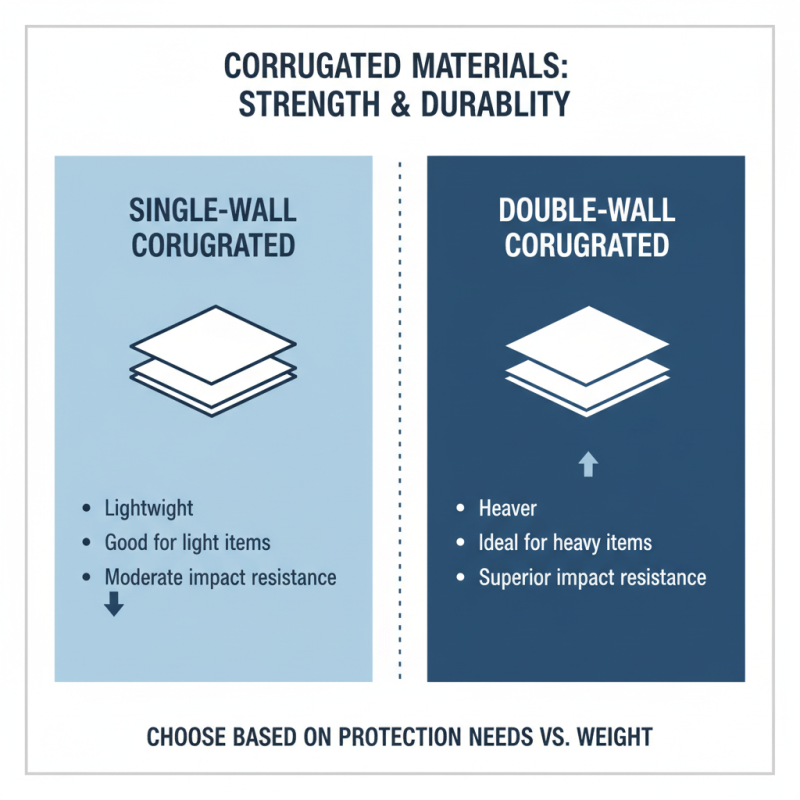

When considering corrugated materials for protection, durability and strength are paramount. Various options exist, from single-wall to double-wall configurations. Single-wall sheets are lightweight but may not withstand heavy impacts. On the other hand, double-wall sheets offer enhanced strength but carry a weight penalty.

Assessing the right material involves specific tests. For instance, puncture resistance can determine how well the sheet endures sharp objects. Additionally, weighing the material's ability to resist bending under pressure is crucial. Applying real-world scenarios often highlights flaws in assumptions about strength. A sheet that seems adequate under low-stress conditions may fail under unexpected loads.

Environmental factors also play an essential role. Certain materials degrade faster under UV light, while others may absorb moisture and weaken. Examining how different corrugated materials perform under specific conditions can save time and resources. Reflecting on past choices helps consumers make better decisions when selecting corrugated sheets. Identify strengths, but learn from weaknesses too.

Best Practices for Cutting and Shaping Corrugated Sheets for Optimal Use

Cutting and shaping corrugated protection sheets requires attention to detail. The right tools can make a significant difference. A utility knife is often ideal for straight cuts. For intricate shapes, use a rotary cutter. Precision in cutting minimizes waste and maximizes the sheet's utility. Avoid the temptation to rush the cutting process. Small errors can lead to larger issues in the application.

When shaping corrugated sheets, consider the intended use. For instance, data shows that correctly shaped sheets enhance structural stability by up to 30%. Measure twice before cutting. This practice reduces mistakes and ensures the final product meets specifications. Additionally, using a straight edge can improve accuracy. Be vigilant—irregular shapes may weaken protection over time.

Remember that corrugated sheets may need reinforcement. Over time, corrections and modifications may be necessary. Inspect your cuts and shapes regularly. Watch for frays or weaknesses. These signs indicate areas that may require reworking. It's not just about the initial application; ongoing adjustments can enhance overall effectiveness. Pay attention to these details for optimal protection.

Top Tips for Using Corrugated Protection Sheets Effectively

Measuring Effectiveness: Industry Standards for Protection Sheet Performance

When it comes to corrugated protection sheets, measuring their effectiveness is crucial. Industry standards provide guidelines for assessing quality. These sheets should resist impacts, moisture, and temperature changes. Understanding these factors helps in choosing the right material for specific needs.

One common mistake is overlooking the thickness of the sheets. Thicker sheets often offer better protection, but may be heavier. This affects the ease of handling. Balancing protection and usability is key. Always check the specifications to ensure the sheets meet the required standards.

Another point to reflect on is the adaptability of the sheets. Some users find they don’t fit perfectly in certain situations. This can lead to gaps that compromise protection. A thorough understanding of the project requirements and limitations is essential. Adjustments may be needed for optimal performance.

Top Tips for Using Corrugated Protection Sheets Effectively

| Dimension | Material Thickness (mm) | Impact Resistance (J/m²) | Moisture Resistance (%) | Cost per Sheet ($) |

|---|---|---|---|---|

| Standard | 3 | 25 | 85 | 10 |

| Heavy-Duty | 5 | 40 | 90 | 15 |

| Ultra-Lightweight | 2 | 20 | 80 | 8 |

| Recycled Material | 4 | 30 | 88 | 12 |

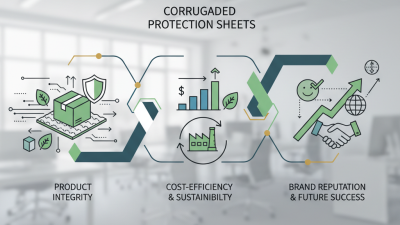

Innovative Applications: How Businesses Utilize Corrugated Sheets for Safety

Businesses are finding innovative ways to use corrugated protection sheets for safety. These versatile sheets are not just for packaging anymore. Companies are using them to create temporary barriers. They can block off areas under construction or protect sensitive equipment. This versatility makes them essential in many workplaces.

In addition to barriers, these sheets are great for cushioning. They can safeguard fragile items during transit. Some companies even use them as flooring protection on job sites. This helps prevent slips and falls. However, not all applications are perfect. Sometimes, the sheets do not stay in place as intended. That can cause hazards if left unaddressed.

Another interesting use is for signage. Businesses create temporary signs from corrugated sheets. They are lightweight and easy to move. But, the printing quality can sometimes be disappointing. Colors may not be as vibrant as expected. Despite these flaws, the creative potential is vast. It allows businesses to enhance safety while being cost-effective. Each application opens doors for new ideas and improvements.

Related Posts

-

7 Unmatched Benefits of Choosing Corrugated Plastic Boxes for Your Business Needs

-

How to Choose the Right Corrugated Plastic Board for Your Business Needs

-

Maximizing Efficiency: How Corrugated Plastic Bins Revolutionize Storage Solutions

-

Why You Should Invest in Corrugated Protection Sheets for Your Business

-

How to Choose the Best Corrugated Protection Sheet for Your Needs?

-

How to Choose the Best PP Corflute Sheet for Your Global Sourcing Needs