- export5@runpingpp.com

- 24 Hours Online

Industry News

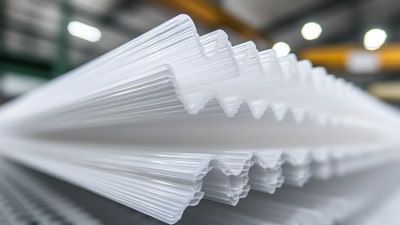

Ultimate Guide to Sourcing High Quality Plastic Corrugated Sheets for Diverse Applications

In recent years, the demand for high-quality Plastic Corrugated Sheets has surged, reflecting a broader trend towards innovative and sustainable packaging solutions across various industries. According to a report by MarketsandMarkets, the global plastic corrugated packaging market is projected to reach USD 36.89 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth can be attributed to the material's exceptional durability, lightweight properties, and recyclability, making it an ideal choice for applications ranging from agricultural containment to industrial packaging. As stakeholders seek to optimize their supply chains while minimizing environmental impact, understanding how to source high-quality Plastic Corrugated Sheets becomes crucial. This ultimate guide aims to provide insights into selecting the best materials tailored for diverse applications, ensuring that businesses stay ahead in a competitive landscape.

Understanding Plastic Corrugated Sheets: Types and Characteristics

Plastic corrugated sheets have gained popularity in various industries due to their versatility and durability. These sheets are typically made from high-density polyethylene (HDPE) or polypropylene, which contribute to their lightweight nature and resistance to moisture, chemicals, and UV radiation. One of the key types of plastic corrugated sheets is the twin-wall design, characterized by its two layers of material that provide additional strength and rigidity, making it ideal for applications like signage, packaging, and even construction.

Another important type is the fluted sheet, which features a wave-like structure that enhances its durability and allows for better insulation properties. This design makes fluted sheets suitable for uses in storage, agriculture, and even as temporary fencing. Understanding the characteristics of these types is crucial when selecting the right sheet for your specific application, ensuring that you make informed decisions based on performance, cost-effectiveness, and durability. Ultimately, the right choice can lead to enhanced functionality and longevity in your projects.

Ultimate Guide to Sourcing High Quality Plastic Corrugated Sheets for Diverse Applications

| Type | Thickness (mm) | Weight (kg/m²) | Color Options | Applications |

|---|---|---|---|---|

| Standard Grade | 3 | 1.5 | White, Blue, Green | Packaging, Signage |

| Food Grade | 4 | 2.0 | Transparent, Frosted | Food Packaging, Displays |

| Industrial Grade | 5 | 2.5 | Black, Grey | Construction, Storage |

| Corrosion Resistant | 6 | 3.0 | White, Yellow | Chemical Containers, Outdoor Use |

Key Advantages of Using High-Quality Plastic Corrugated Sheets

When it comes to sourcing high-quality plastic corrugated sheets, the key advantages these materials offer can significantly impact a range of industries. According to a recent report by Grand View Research, the global plastic sheets market is projected to reach $45.56 billion by 2025, with corrugated plastic sheets gaining popularity due to their lightweight yet durable properties. This versatility makes them an ideal choice for packaging, construction, and signage applications, where both resilience and cost-effectiveness are paramount.

High-quality plastic corrugated sheets provide superior moisture resistance and UV protection, making them suitable for outdoor use as well as in humid environments. A study by Research and Markets indicates that the demand for durable packaging solutions is expected to grow at a CAGR of 5.7% from 2021 to 2028. This growth is largely attributed to industries seeking sustainable and reliable materials that can withstand environmental challenges. With their recyclable nature, these sheets not only promote eco-friendliness but also help companies meet regulatory standards, making them a standout option for sustainability-focused businesses.

Applications of Plastic Corrugated Sheets Across Industries

Plastic corrugated sheets have become an essential material across various industries due to their durability, lightweight, and versatility. In construction, these sheets are utilized for temporary barriers and coverings, offering protection and functionality in both outdoor and indoor settings. According to the Plastic News 2022 report, the construction sector accounts for approximately 30% of the plastic corrugated sheet market, highlighting its importance in ensuring safety and ease of installation on job sites.

Plastic corrugated sheets have become an essential material across various industries due to their durability, lightweight, and versatility. In construction, these sheets are utilized for temporary barriers and coverings, offering protection and functionality in both outdoor and indoor settings. According to the Plastic News 2022 report, the construction sector accounts for approximately 30% of the plastic corrugated sheet market, highlighting its importance in ensuring safety and ease of installation on job sites.

In the packaging industry, plastic corrugated sheets are praised for their moisture resistance and structural strength, making them ideal for shipping and storage solutions. A study by Smithers Pira indicates that the demand for sustainable packaging solutions is rising significantly, and plastic corrugated sheets meet these requirements by being both recyclable and cost-effective. Businesses looking to enhance their packaging processes can benefit from integrating these sheets into their supply chain.

Tips: When sourcing plastic corrugated sheets, prioritize manufacturers that utilize recycled materials to support sustainability goals. Additionally, always request samples to assess the quality before bulk purchasing, ensuring that the sheets meet your specific application needs. Regularly review industry reports to stay updated on emerging trends and innovations related to plastic corrugated applications.

Factors to Consider When Sourcing Plastic Corrugated Sheets

When sourcing plastic corrugated sheets, several critical factors should be taken into account to ensure you select the right product for your specific needs. First and foremost, the thickness and density of the sheets play a vital role in determining their strength and durability. Thicker sheets typically provide better structural integrity, making them suitable for heavy-duty applications. Additionally, understanding the specific environmental conditions where the sheets will be used—such as exposure to sunlight, moisture, or chemicals—is essential to select materials that can withstand these challenges.

Another key consideration is the manufacturing process of the plastic corrugated sheets. Different production methods can affect the quality and consistency of the sheets. Look for suppliers who utilize advanced technologies while adhering to industry standards, as this often results in superior products. Moreover, evaluating the supplier's reputation and customer feedback can offer insights into their reliability and the performance of their sheets in real-world applications. By taking these factors into account, you can make informed decisions that align with your project requirements and ensure long-lasting performance.

Tips for Choosing the Right Supplier for Plastic Corrugated Sheets

When sourcing high-quality plastic corrugated sheets, choosing the right supplier is crucial to ensure the material meets your specific application needs. First, evaluate potential suppliers by examining their experience and reputation in the industry. Look for companies that specialize in plastic products, as they are more likely to have the necessary expertise and knowledge of the latest manufacturing techniques. Reading reviews and testimonials can also provide insights into their reliability and product quality.

Another important aspect to consider is the supplier's capability to provide customized solutions. Each application may require different specifications, such as thickness, color, or UV resistance. A good supplier should be willing to collaborate with you to develop sheets that fit your requirements perfectly. Additionally, ensure that they adhere to quality control standards and can provide certifications to guarantee the durability and performance of their products. This attention to quality and collaboration will result in a smoother sourcing process and ultimately lead to better outcomes for your projects.

Related Posts

-

Unlocking the Advantages of Using the Best Corrugated Plastic Rolls for Your Business Needs

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

Advantages of Using Best Corrugated Plastic Rolls for Your Business Needs

-

Unmatched Quality in Best Plastic Corrugated Pads: China’s Leading Export Solution

-

Exceptional Manufacturing of Best Corrugated Plastic from China Serving the Global Market