- export5@runpingpp.com

- 24 Hours Online

Industry News

2025 How to Use Plastic Corrugated Sheets for Your Next Project

Plastic Corrugated Sheets have become an increasingly popular choice in various industries due to their durability, lightweight nature, and versatility. As we approach 2025, understanding how to effectively utilize these sheets in your next project is more important than ever. Whether you're in construction, packaging, or event planning, the unique properties of Plastic Corrugated Sheets can enhance your projects, providing solutions that are both practical and cost-effective.

In this article, we will explore the numerous applications of Plastic Corrugated Sheets and guide you through the best practices for incorporating them into your work. From serving as protective packaging materials to acting as temporary signage structures, these sheets offer strength and resilience that traditional materials may lack. We will also discuss key considerations when selecting the right type of sheet for your specific needs, ensuring successful outcomes across various projects. Join us as we delve into the innovative uses of Plastic Corrugated Sheets and unlock their potential for your next endeavor.

Understanding Plastic Corrugated Sheets: Types and Properties

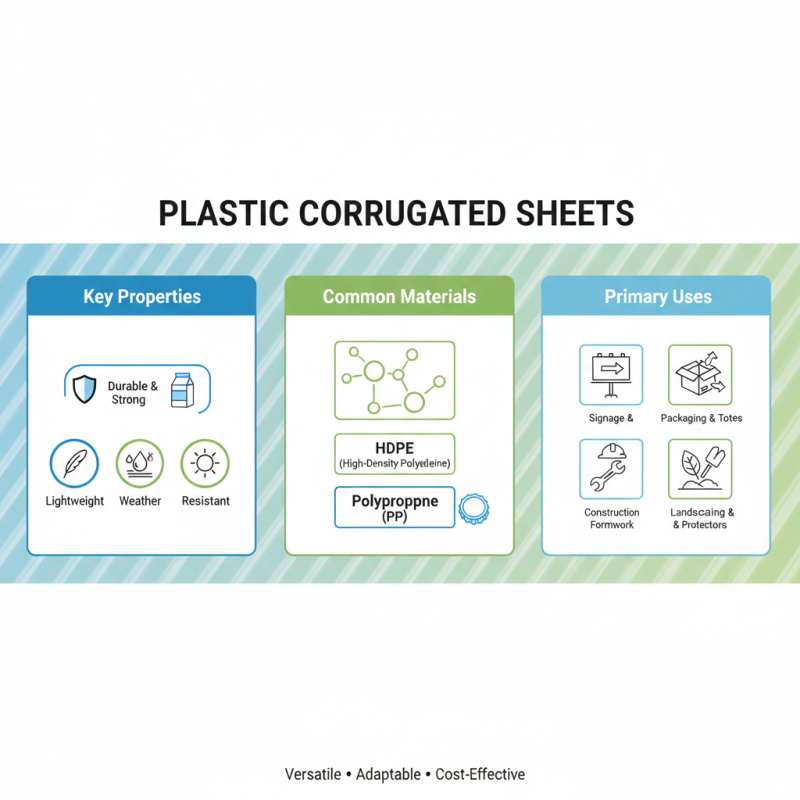

Plastic corrugated sheets are versatile materials known for their durable construction and lightweight properties. Typically made from high-density polyethylene (HDPE) or polypropylene, these sheets consist of a fluted structure that provides excellent strength-to-weight ratios. This makes them suitable for a variety of uses, from signage and packaging to construction and landscaping applications. Understanding the types of plastic corrugated sheets available is crucial for selecting the right one for your project.

There are different variations of plastic corrugated sheets, including twin-wall and triple-wall configurations. Twin-wall sheets feature two layers with a honeycomb-like core, offering a good balance between weight and strength, while triple-wall sheets provide enhanced rigidity and insulation. The thickness of the sheets can also vary, impacting their overall durability and application suitability. Additionally, plastic corrugated sheets are water-resistant, UV-stabilized, and available in a range of colors, making them ideal for both indoor and outdoor projects. By understanding these properties, you can effectively choose the right plastic corrugated sheet to meet your project's specific needs.

Advantages of Using Plastic Corrugated Sheets in Various Projects

Plastic corrugated sheets have gained popularity in various projects due to their unique advantages. These lightweight yet sturdy sheets are made from high-density polyethylene (HDPE) or polypropylene, offering exceptional durability and weather resistance. According to a report by Smithers Pira, the global market for corrugated plastic sheets is projected to grow at a CAGR of over 5% by 2025, driven by increased demand across construction, packaging, and signage applications. Their ability to withstand harsh environmental conditions makes them ideal for outdoor use, whether in temporary structures, garden beds, or protective barriers.

One of the standout features of plastic corrugated sheets is their versatility. They can be easily cut, bent, or shaped to fit any project requirement, making them suitable for both industrial and DIY applications. Additionally, their reusable nature promotes sustainability, aligning with current trends in eco-friendly construction materials. A study by Freedonia Group indicates that recycled content in plastic products is a key driver for the industry, highlighting the increasing preference for environmentally responsible materials.

Tips: When using plastic corrugated sheets, ensure proper sealing at the edges to enhance water resistance, especially for outdoor projects. Additionally, consider using UV-stabilized sheets for prolonged exposure to sunlight. This not only extends the lifespan of your project but also maintains the aesthetic quality of the material over time.

2025 How to Use Plastic Corrugated Sheets for Your Next Project - Advantages of Using Plastic Corrugated Sheets in Various Projects

| Project Type | Advantages | Common Uses | Durability |

|---|---|---|---|

| Signage | Lightweight, weather-resistant, customizable | Outdoor signs, event displays | High durability against UV and moisture |

| Packaging | Reusable, recyclable, cushioning properties | Shipping containers, product display trays | Strong and resistant to impact |

| Construction | Cost-effective, moisture-resistant, versatile | Temporary walls, dust barriers | Withstands harsh conditions |

| Event Management | Easily portable, quick setup, different sizes | Booths, barriers, decoration | Reliable under various weather conditions |

| Agriculture | Lightweight, durable, non-toxic | Plant protection, garden starters | Effective against pests and harsh weather |

Step-by-Step Guide to Cutting and Shaping Plastic Corrugated Sheets

When it comes to using plastic corrugated sheets for your next project, proper cutting and shaping are essential to ensure a clean and precise outcome. To start, gather your materials, including a utility knife or a circular saw, scissors, and a cutting mat. If you're using a utility knife, place the sheet on the cutting mat for protection. Measure and mark your desired dimensions with a straightedge, ensuring that your lines are straight and clear for the best results.

Next, if you are using a utility knife, apply gentle pressure along the marked line, allowing the blade to score the sheet. For thicker sheets, you'll need to make multiple passes until the cut is deep enough to break through. If you're using a circular saw, set the blade to a moderate speed to prevent melting the plastic, and guide the sheet steadily to achieve an even cut. After cutting, you may need to trim the edges for a smoother finish, which can be easily done with scissors or by running the utility knife along the edges again.

Shaping plastic corrugated sheets requires a different approach. Heat can be used to bend the plastic without breaking it. Use a heat gun to apply even heat along the area where you want to create a bend. Once the material becomes pliable, carefully shape it to your desired angle, holding it in place until it cools and stabilizes. Ensure you work in a well-ventilated area when using heat tools. Following these steps will help you effectively cut and shape plastic corrugated sheets for a variety of projects, allowing for creativity and customization.

Plastic Corrugated Sheets Usage Guide in 2025

This bar chart represents the estimated time (in hours) required for different stages of working with plastic corrugated sheets in 2025. Proper planning can help streamline your project for best results.

Best Practices for Installing Plastic Corrugated Sheets in Your Project

When it comes to incorporating plastic corrugated sheets into your next project, following best practices for installation is essential to ensure durability and functionality. Begin by selecting the appropriate thickness and size of the sheets based on the specific requirements of your project. Consider factors such as exposure to sunlight, humidity, and potential wear and tear. This initial step will set the foundation for a successful installation.

Before installation, ensure that the surface area is clean and free of debris. This will enhance adhesion and longevity. Use a straight edge and a measuring tape to determine accurate cuts, and opt for a fine-toothed saw for smoother edges. During the installation, overlap the sheets appropriately to prevent water infiltration, especially in roofing applications. To secure the sheets, use compatible fasteners that won’t corrode over time, maintaining the integrity of the material.

Tips for installation include pre-drilling holes to avoid cracking the sheets, as plastic can become brittle if too much force is applied. Additionally, when working with larger sheets, consider getting a helping hand to manage the weight and ensure proper alignment. Lastly, allow for expansion and contraction by leaving a small gap at the edges, accommodating temperature fluctuations while avoiding buckling.

Creative Applications of Plastic Corrugated Sheets in Design and Construction

Plastic corrugated sheets, known for their durability and versatility, are increasingly being adopted in various design and construction projects. According to a report by Smithers Pira, the global market for corrugated plastic sheets is projected to grow by 4.1% annually, reaching a value of approximately $2.5 billion by 2025. This growth can be attributed to the material's ability to withstand harsh weather conditions and physical impacts, making it an ideal choice for both indoor and outdoor applications.

In design, corrugated plastic sheets can be used creatively for signage, partition walls, and temporary installations. Their lightweight nature allows for easy handling and installation, while their customizable colors and textures can enhance aesthetic appeal. Moreover, in construction, these sheets serve as excellent alternatives for traditional building materials, offering insulation, moisture resistance, and ease of maintenance. A study by the Plastic Industry Association highlights that using corrugated plastics can reduce overall material costs by up to 20%, promoting sustainability and cost-effectiveness in building projects.

As the construction industry seeks innovative solutions to reduce waste and improve efficiency, the adoption of plastic corrugated sheets showcases a significant shift towards eco-friendly practices. Their application in reusable packaging, protective barriers, and even as a component in modular designs illustrates the potential to not only enhance functionality but also contribute to a more sustainable future in construction and design.

Related Posts

-

Understanding the Benefits of Pp Corrugated Board: A Sustainable Choice for Packaging Solutions

-

Ultimate Guide to Creating Effective Corrugated Signs for Your Business

-

Understanding the Versatility of White Corrugated Sign Boards in Modern Marketing Strategies

-

Maximizing Efficiency: How Corrugated Plastic Bins Revolutionize Storage Solutions

-

Discovering Quality Suppliers for Best White Corrugated Sign Boards Effective Strategies for Global Buyers

-

Innovative Solutions for Your Best Pp Corrugated Plastic Box Packaging Needs