- export5@runpingpp.com

- 24 Hours Online

Industry News

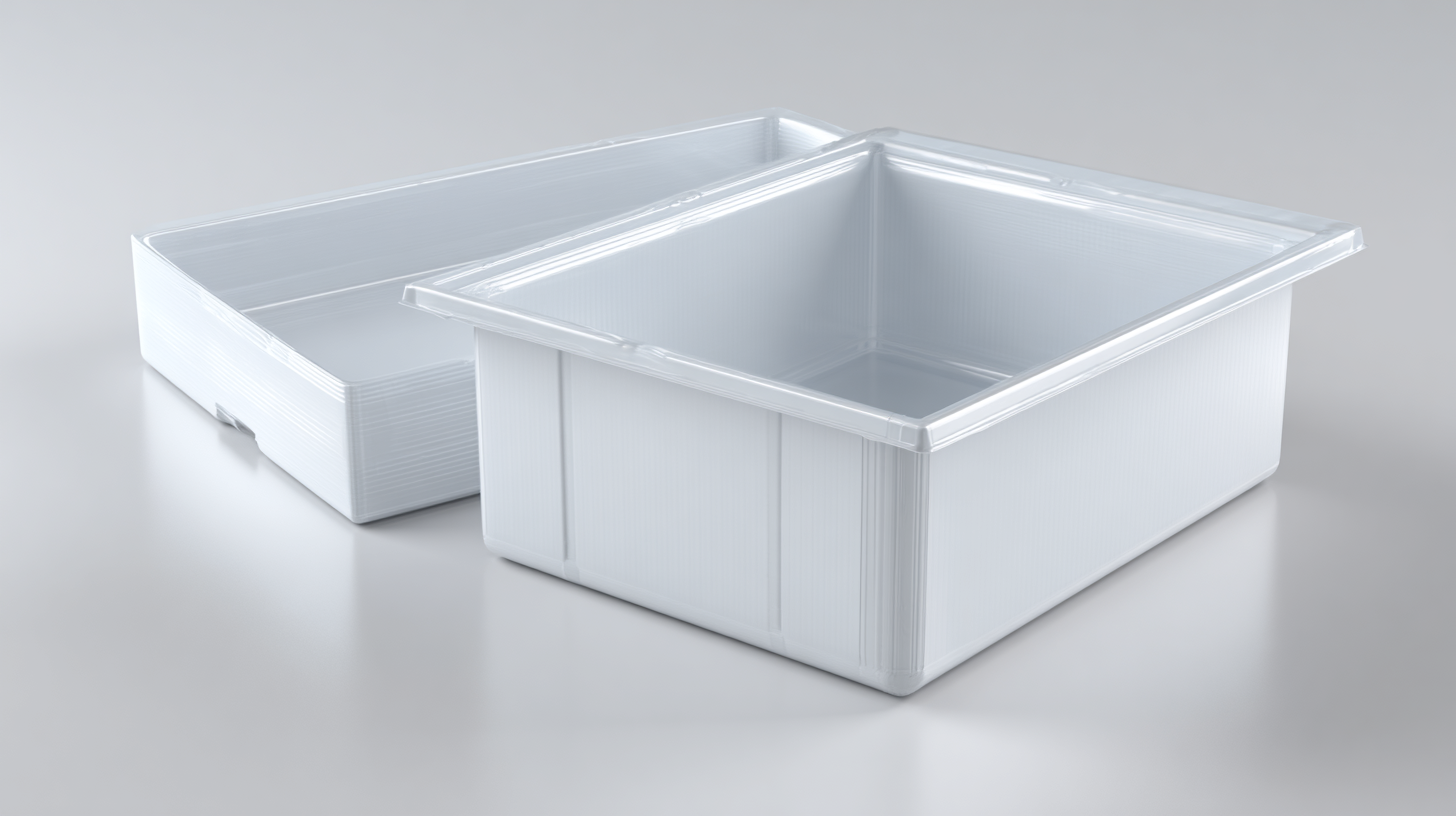

What is a Pp Corrugated Plastic Box and Why is it Your Best Packaging Solution?

The packaging industry is constantly evolving, and one of the most

innovative solutions gaining traction is the

Pp Corrugated Plastic Box. According to a report by

Smithers Pira, the global market for corrugated plastic packaging is expected to grow at a

CAGR of 4.5% from 2021 to 2026, underscoring the rising demand

for durable and sustainable packaging options. Pp Corrugated Plastic Boxes stand out due to their

reusable nature and resistance to moisture, which significantly reduces waste and enhances

logistics efficiency. In fact, a study by Freedonia Group revealed that companies adopting plastic

corrugated packaging reported a

20% decrease in shipping damage and a

15% reduction in overall packaging costs. This makes the

Pp Corrugated Plastic Box not only a practical choice

but also a strategic investment for businesses looking to

optimize their supply chains while adhering to sustainability initiatives.

The packaging industry is constantly evolving, and one of the most

innovative solutions gaining traction is the

Pp Corrugated Plastic Box. According to a report by

Smithers Pira, the global market for corrugated plastic packaging is expected to grow at a

CAGR of 4.5% from 2021 to 2026, underscoring the rising demand

for durable and sustainable packaging options. Pp Corrugated Plastic Boxes stand out due to their

reusable nature and resistance to moisture, which significantly reduces waste and enhances

logistics efficiency. In fact, a study by Freedonia Group revealed that companies adopting plastic

corrugated packaging reported a

20% decrease in shipping damage and a

15% reduction in overall packaging costs. This makes the

Pp Corrugated Plastic Box not only a practical choice

but also a strategic investment for businesses looking to

optimize their supply chains while adhering to sustainability initiatives.

What Makes Pp Corrugated Plastic Boxes Stand Out in Packaging?

Pp corrugated plastic boxes are increasingly recognized for their outstanding features that enhance packaging solutions. These boxes stand out in the packaging landscape due to their durability, lightweight structure, and resistance to water and chemicals. This makes them ideal for various applications, particularly in the booming direct-to-consumer (DTC) packaging market, which is projected to see revenues surge into the hundreds of millions by 2034, as per recent industry analysis. The flexibility of Pp corrugated plastic boxes also aligns perfectly with key trends, including the demand for renewable, recyclable, and reusable materials that optimize product protection.

Tips for utilizing Pp corrugated plastic boxes effectively include customizing the boxes to resonate emotionally with consumers, a growing demand driven by the popularity of unboxing videos on social media. Brands are increasingly seeking tailored packaging solutions that not only safeguard products but also create a memorable consumer experience. Moreover, incorporating in-box printing can enhance brand visibility while promoting sustainability, a crucial element given that packaging innovations are shifting towards environmentally friendly practices.

By adopting Pp corrugated plastic boxes, businesses can not only prepare for the anticipated expansion of the packaging market but also appeal to the environmentally conscious consumer. The flexibility and innovative potential of these boxes support both functionality and sustainability in the evolving packaging industry landscape.

What is a Pp Corrugated Plastic Box and Why is it Your Best Packaging Solution? - What Makes Pp Corrugated Plastic Boxes Stand Out in Packaging?

| Feature | Description | Advantages |

|---|---|---|

| Durability | Made from high-density polypropylene, these boxes are resistant to water, chemicals, and UV light. | Long-lasting and withstand harsh conditions, reducing the need for replacements. |

| Lightweight | Designed to be lightweight without compromising strength. | Lower shipping costs and easier handling. |

| Recyclability | 100% recyclable material promotes sustainability. | Environmentally friendly option, appealing to eco-conscious consumers. |

| Customizability | Available in various sizes and colors, with options for printing. | Branding opportunities and tailored solutions for specific needs. |

| Stackability | Designed to stack efficiently, maximizing storage space. | Optimizes warehouse storage and transportation efficiency. |

The Environmental Benefits of Using Pp Corrugated Plastic Boxes

PP corrugated plastic boxes have quickly gained traction as a sustainable packaging solution, primarily due to their significant environmental benefits. Unlike traditional cardboard, these boxes are reusable and recyclable, drastically reducing waste. According to a report from the Plastic Industry Association, the recycling rate for polypropylenes like those used in these boxes has been steadily climbing, reaching approximately 25% in recent years. This not only minimizes landfill contributions but also cuts down on the carbon footprint associated with packaging.

In addition to their recyclability, PP corrugated plastic boxes are durable and can withstand various environmental conditions, which extends their life cycle. A study published in the Journal of Cleaner Production indicates that transitioning to plastic corrugated packaging can reduce greenhouse gas emissions by an average of 30%. This makes them an excellent choice for companies looking to improve their sustainability profiles while also maintaining cost-effectiveness.

Tips: When considering PP corrugated plastic boxes, assess their intended use properly—opting for boxes designed for reuse can significantly enhance your packaging's environmental impact. Additionally, always ensure your supplier has a take-back program for recycling, which can further close the loop on your packaging lifecycle.

Key Features of Pp Corrugated Plastic Boxes That Enhance Your Packaging Experience

PP corrugated plastic boxes represent a significant innovation in packaging solutions, particularly tailored to meet the burgeoning demands of various industries, including the automotive sector. As highlighted by data from the Plastics Industry Association, polypropylene (PP) is the most utilized plastic in automotive manufacturing, fostering a robust growth trend as manufacturers increasingly seek lightweight and durable materials. This trend underscores the necessity for packaging that can withstand rigorous transportation and handling processes, characteristics that PP corrugated plastic boxes excel at.

PP corrugated plastic boxes represent a significant innovation in packaging solutions, particularly tailored to meet the burgeoning demands of various industries, including the automotive sector. As highlighted by data from the Plastics Industry Association, polypropylene (PP) is the most utilized plastic in automotive manufacturing, fostering a robust growth trend as manufacturers increasingly seek lightweight and durable materials. This trend underscores the necessity for packaging that can withstand rigorous transportation and handling processes, characteristics that PP corrugated plastic boxes excel at.

The key features of PP corrugated plastic boxes that enhance the packaging experience include their exceptional strength-to-weight ratio, water resistance, and recyclability. Their lightweight nature not only reduces shipping costs but also minimizes carbon footprints, an essential consideration for manufacturers facing increasing environmental scrutiny. Furthermore, the durability of these boxes ensures they can be reused multiple times, making them a cost-effective solution in the long run.

Industry forecasts suggest a significant expansion in the use of PP in various applications, from food packaging to industrial shipping, highlighting that adopting PP corrugated plastic boxes may be the best decision for companies looking to optimize their packaging processes and meet consumer expectations.

How Pp Corrugated Plastic Boxes Compare to Traditional Packaging Solutions

PP corrugated plastic boxes have emerged as a preferred choice over traditional packaging solutions, particularly in industries like seafood distribution. This is primarily due to their durability and reusability, significantly reducing waste compared to single-use materials such as expanded polystyrene (EPS) boxes. In a comprehensive life cycle analysis, it has been demonstrated that while traditional packaging might be cost-effective upfront, the long-term environmental impact, including weight during transportation and subsequent disposal issues, often outweighs the benefits.

When comparing PP corrugated plastic boxes to traditional options, one must consider factors such as resource efficiency and transportation logistics. The lighter weight of PP boxes contributes to reduced transportation costs and lower carbon emissions. Moreover, they are designed to withstand harsh conditions, ensuring that products remain safe during transit.

Tips: When selecting packaging, always assess the environmental impact in terms of life cycle analysis. Consider the durability and reusability of materials to minimize waste. Additionally, analyze transportation costs related to weight; a lighter package can lead to significant savings in logistics.

Top Industries Benefiting from Pp Corrugated Plastic Box Usage

PP corrugated plastic boxes have emerged as a versatile packaging solution across various industries, primarily due to their durability and lightweight nature. One of the key sectors benefiting from this innovation is the food industry. These boxes provide superior resistance to moisture and pests, making them ideal for transporting perishable goods safely. Moreover, their ability to withstand temperature variations ensures that products maintain quality throughout the supply chain, ultimately enhancing customer satisfaction.

In addition to the food sector, the automotive and electronics industries are also leveraging PP corrugated plastic boxes. In the automotive sector, these boxes are used for parts storage and distribution, ensuring that components remain undamaged during transport. Similarly, the electronics industry values these boxes for their static-dissipative properties, which help in preventing damage to sensitive electronic components. Overall, the adaptability and protective characteristics of PP corrugated plastic boxes make them a preferred choice in numerous fields, promoting efficiency and reliability in packaging solutions.

Related Posts

-

The Ultimate Guide to Understanding Corrugated Pp Box Features Benefits and Applications

-

How to Choose the Right Pp Corrugated Box for Your Packaging Needs

-

How to Effectively Use Corflute Sheets for Your Business Needs

-

10 Amazing Ways to Use Best Corrugated Pp in Your Business

-

How to Choose the Right Pp Corrugated Sheet for Your Business Needs

-

Ultimate Checklist for Choosing the Best Corrugated PP Products for Your Business Needs