- export5@runpingpp.com

- 24 Hours Online

Industry News

Discovering Quality Suppliers for Best White Corrugated Sign Boards Effective Strategies for Global Buyers

In the fast-paced world of advertising and branding, the need for durable and eye-catching materials like White Corrugated Sign Boards has never been more critical. According to a recent report by Smithers Pira, the global demand for corrugated packaging materials is projected to reach over 200 million tons by 2025, driven significantly by the rising trend of sustainable packaging solutions. This compelling growth reflects a broader transition toward eco-friendly materials, aligning perfectly with the attributes of White Corrugated Sign Boards, known for their lightweight yet robust structure. For global buyers seeking to invest wisely in their branding efforts, discovering quality suppliers in China, a country noted for its manufacturing excellence, is vital. As the phrase "世界级的制造,中国骄傲,出口全球" suggests, the synergy of quality and affordability can pave the way for effective branding, making it imperative for businesses to develop effective strategies in supplier selection.

Understanding the Characteristics of White Corrugated Sign Boards

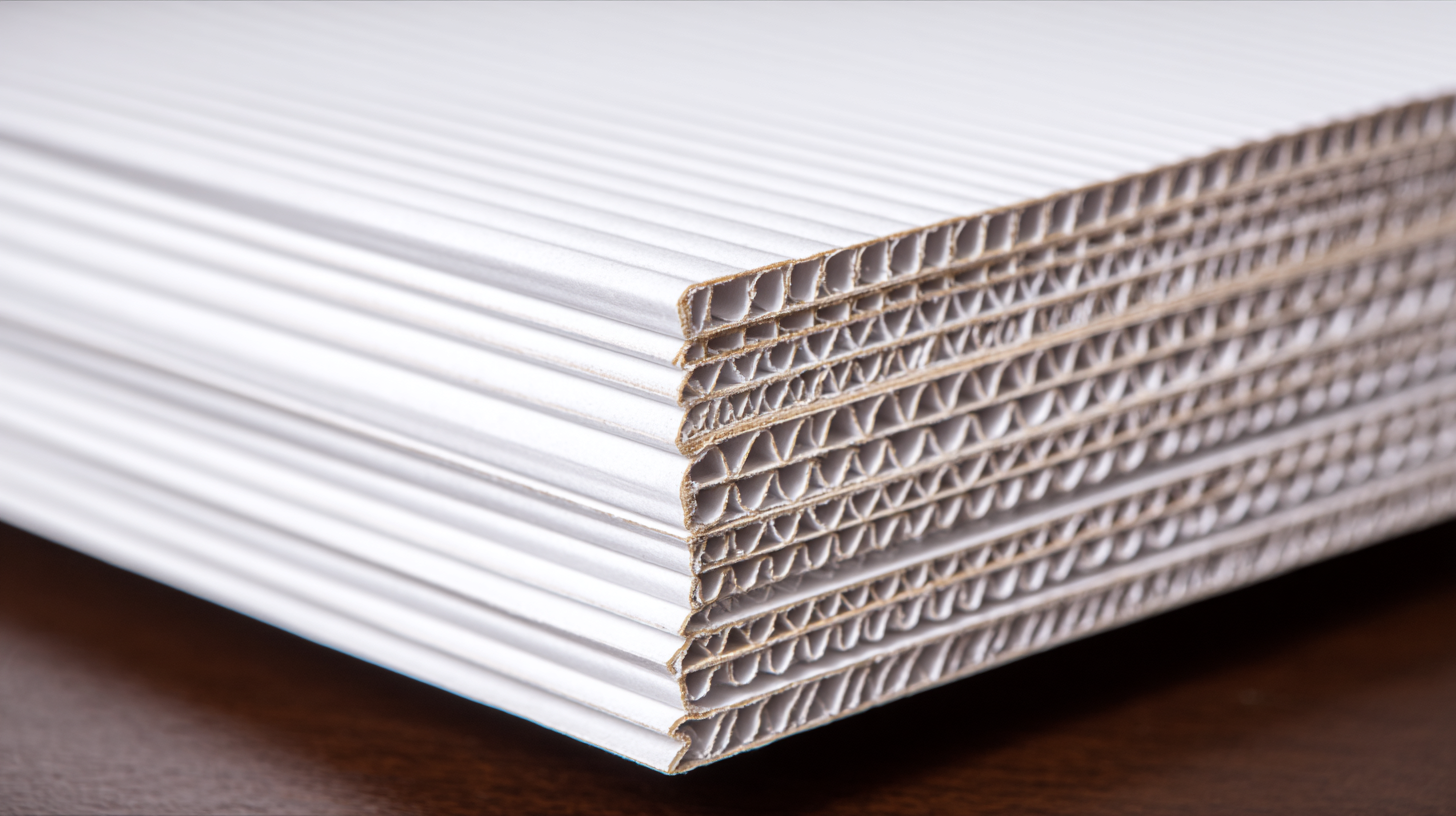

When exploring the realm of white corrugated sign boards, understanding their key characteristics is essential for making informed purchasing decisions. These boards are primarily made from a fluted cardboard material, which gives them the strength and durability needed for both indoor and outdoor use. Their lightweight nature allows for easy handling and installation, making them a popular choice for various signage applications—from advertising promotions to event guidance.

Another significant attribute of white corrugated sign boards is their superior printability. The smooth, white surface provides an ideal canvas for vibrant graphics and bold text, ensuring that your message stands out. Furthermore, they are often resistant to moisture and can withstand different weather conditions without fading. This makes them an excellent option for businesses looking to maintain visibility and professionalism across diverse environments. Their versatility and effectiveness under various circumstances make white corrugated sign boards a preferred choice among global buyers seeking quality signage solutions.

Evaluating Different Types of White Corrugated Sign Boards for Various Applications

When it comes to choosing white corrugated sign boards, understanding the different types available is essential for making the best choice for your specific needs. These sign boards come in various strengths and thicknesses, catering to diverse applications such as event signage, real estate advertising, and point-of-purchase displays. For temporary outdoor use, opt for thicker boards that can withstand elements without bending. Conversely, lightweight boards are suitable for indoor use where durability is less of a concern.

Tip: Always consider your project’s requirements—whether it be resistance to weather, weight limitations, or printability—before making a decision on the type of corrugated board. This will ensure that your signage is not only effectively displayed but also long-lasting.

Moreover, it's crucial to evaluate the print quality and finish of the boards. Some boards offer a smoother surface ideal for high-resolution graphics, while others may be more suited for simple text or graphics. Choosing the right finish can significantly affect the visibility and impact of your message.

Tip: Test samples of different boards with your intended graphics to ascertain which material provides the best clarity and vibrancy. This hands-on approach can save time and money in the long run.

Key Factors to Consider When Selecting Suppliers for Sign Boards

When selecting suppliers for white corrugated sign boards, several key factors must be considered to ensure you are partnering with a reliable and quality-focused provider. According to a report by Smithers Pira, the global corrugated board market was valued at approximately $259 billion in 2021 and is projected to grow significantly, with sustainable solutions driving demand. This rapid growth highlights the importance of choosing suppliers who not only deliver high-quality products but also adhere to sustainable practices.

Another critical factor is the supplier's production capabilities and technology. Research from MarketsandMarkets indicates that advancements in manufacturing technologies can enhance production efficiency, thereby reducing costs and lead times. It is essential to assess whether the supplier is equipped with state-of-the-art machinery and can handle large volume orders while maintaining consistency in quality. Furthermore, evaluating suppliers’ certifications, such as ISO standards, can provide additional assurance of their commitment to quality control and industry best practices. By focusing on these factors, global buyers can effectively navigate their supplier selection process, ensuring reliable sourcing of top-quality sign boards.

Best Practices for Global Buyers in Sourcing Quality Sign Boards

When sourcing quality white corrugated sign boards, global buyers should adopt a systematic approach to ensure they partner with reliable suppliers. One of the best practices is to conduct thorough market research to identify potential suppliers who specialize in high-quality signage products. This can involve looking into various factors, such as the supplier’s reputation, production capacity, and the materials they use. Leveraging platforms that host supplier ratings and reviews can also provide valuable insights into the reliability and quality of different manufacturers.

Additionally, establishing clear communication channels with potential suppliers is crucial. Buyers should articulate their specific requirements, including design specifications, quality standards, and delivery timelines. Requesting samples can further help assess the quality of the boards before committing to a larger order. Furthermore, it’s beneficial to build long-term relationships with suppliers by visiting their production facilities, understanding their processes, and discussing ways to improve efficiency and quality. By implementing these strategies, buyers can effectively navigate the global market and secure the best white corrugated sign boards for their needs.

How to Assess the Quality and Durability of Corrugated Products

When sourcing white corrugated sign boards, quality and durability are paramount for global buyers. According to a 2022 market report from Smithers Pira, corrugated board is projected to grow at a CAGR of 4.5% through 2027, underscoring the increasing reliance on this material for various applications, including signage. Assessing the quality of corrugated products can be achieved through several key metrics, including weight, flute profile, and materials used. A thicker flute provides better durability while heavier boards demonstrate resistance to bending and environmental stress.

Tip: Always request samples of the sign boards before making a bulk purchase. Test their rigidity and moisture resistance to ensure they meet your specific needs. Additionally, reviewing certifications, like FEFCO standards for fluted board, can provide insight into the quality and sustainability of the products.

One effective strategy in assessing durability is to consider the environmental factors that the signs will face. According to the Paper and Allied Products Manufacturing Association, exposure to elements like UV light and moisture can deteriorate lower-quality boards within months. Ensure to choose products that are specifically designed for outdoor use, incorporating weather-resistant coatings to extend their lifespan.

Tip: Conduct comparative testing by exposing samples to simulated environmental conditions for a set period. This can help identify the most robust options for your projects.