- export5@runpingpp.com

- 24 Hours Online

Industry News

Selecting the Right Manufacturer for Best Corflute Sheet Based on Industry Insights and Data

In today's competitive landscape, selecting the right manufacturer for Corflute Sheet is crucial for businesses aiming to optimize their operations and enhance product quality.

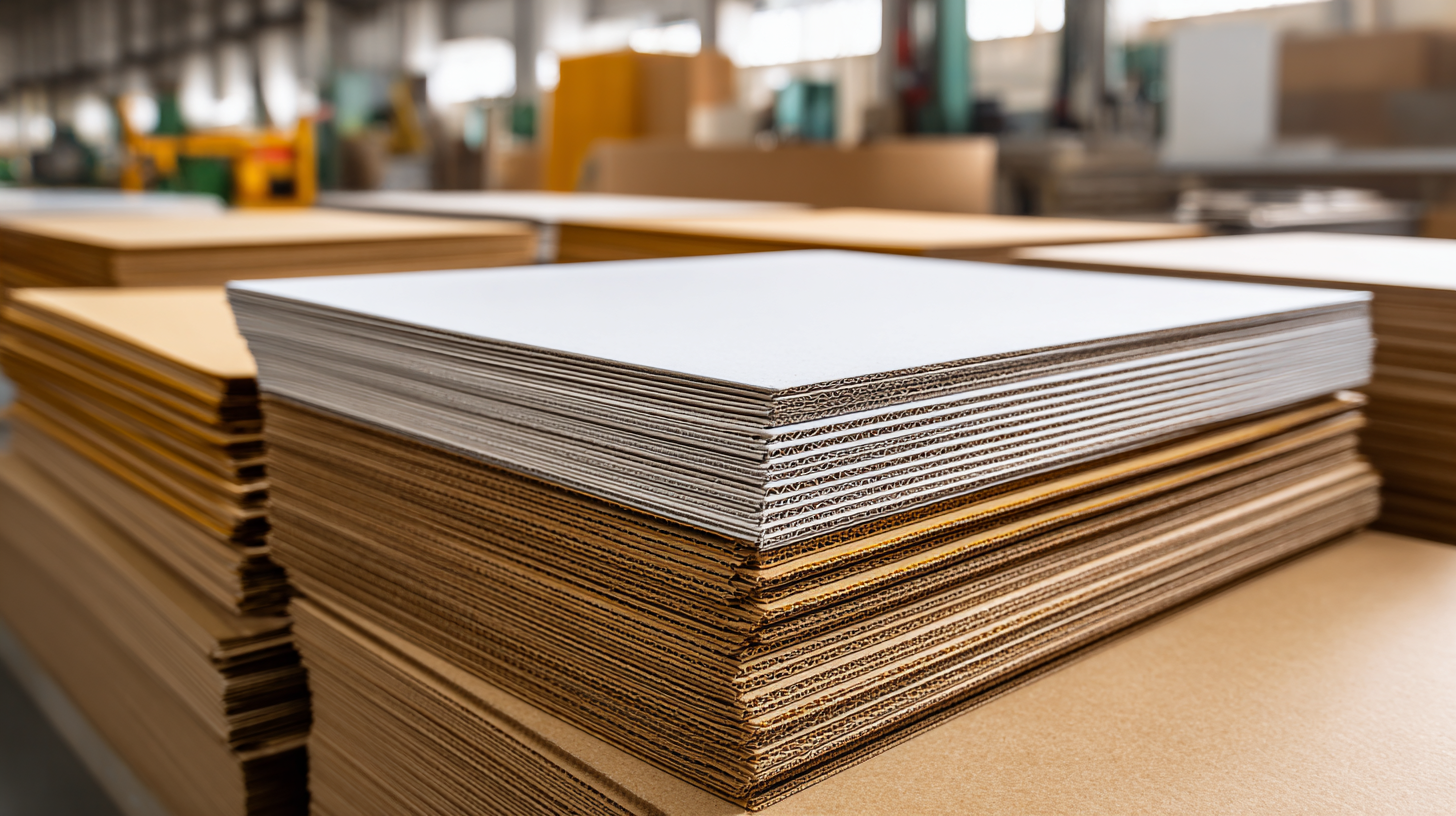

Corflute Sheets, known for their durability, lightweight nature, and versatility, are widely used across various industries, from construction and logistics to signage and event management.

Understanding the benefits of choosing the right supplier can significantly impact production efficiency and the final product's effectiveness.

This blog delves into key insights and data-driven considerations to help companies make informed decisions when selecting a manufacturer for Corflute Sheets.

Corflute Sheets, known for their durability, lightweight nature, and versatility, are widely used across various industries, from construction and logistics to signage and event management.

Understanding the benefits of choosing the right supplier can significantly impact production efficiency and the final product's effectiveness.

This blog delves into key insights and data-driven considerations to help companies make informed decisions when selecting a manufacturer for Corflute Sheets.

By evaluating factors such as material quality, cost-effectiveness, and manufacturing capabilities, businesses can ensure they partner with a supplier that meets their specific needs and contributes to their overall success.

Understanding After-Sales Service Benefits in Corflute Sheet Manufacturing

When selecting a manufacturer for corflute sheets, understanding the after-sales service benefits can significantly impact your overall satisfaction and project success. A reliable manufacturer does not just stop at delivering quality products; they also offer robust after-sales support that can address any concerns or issues that may arise after installation. This kind of support ensures that you have access to expertise and assistance, helping you to resolve problems quickly and efficiently. For instance, if there are defects or if the corflute sheets require specific maintenance, a responsive after-sales service can save you time and avoid unnecessary costs.

Additionally, strong after-sales service often includes providing valuable insights and recommendations tailored to your precise needs. Whether it's guidance on how to maximize the longevity of your corflute sheets or advice on the best applications for your industry, a manufacturer that prioritizes after-sales service can enhance your overall experience. They may offer training sessions or resource materials that can help your team effectively use and care for the product, leading to better outcomes and productivity. In conclusion, prioritizing after-sales service when choosing a corflute sheet manufacturer can play a critical role in ensuring your investment pays off long-term.

Analyzing Repair Costs: Key Factors Impacting Corflute Sheet Longevity

When assessing the longevity of corflute sheets, one must consider various factors that contribute to repair costs, ultimately impacting their overall effectiveness in an industrial setting. According to a report from the Plastics Industry Association, corflute sheets typically exhibit a lifespan of 5 to 10 years depending on environmental conditions and usage patterns. Over time, damage such as UV degradation, moisture exposure, and physical wear can lead to increased repair and replacement costs, which can vary significantly across different industries.

In a recent analysis by the International Association of Plastics Manufacturers, it was found that improper storage and handling can increase repair costs by up to 30%. This is crucial for manufacturers relying on corflute sheets for applications such as signage, packaging, and construction. By investing in high-quality materials and implementing best practices for maintenance, industries can mitigate these costs. Furthermore, selecting the right manufacturer can also play a pivotal role; research shows that sourcing corflute sheets with UV stabilization can reduce repair frequency by nearly 25%, effectively enhancing their durability and reducing long-term expenses.

Case Studies: Successful After-Sales Strategies in Corflute Industries

In the rapidly evolving corflute industry, successful after-sales strategies are pivotal for maintaining customer loyalty and enhancing brand reputation. Companies that excel in after-sales support not only ensure customer satisfaction but also drive repeat business. One effective strategy observed in various case studies involves implementing tailored communication channels, such as dedicated support lines or online chat systems, which provide immediate assistance to customers post-purchase. These proactive measures show customers that their needs are prioritized, fostering a sense of reliability and trust.

Moreover, leveraging feedback loops is another essential tactic for success in after-sales strategies. By actively seeking customer feedback on their experience and product performance, manufacturers can identify areas for improvement and innovate product offerings. This continuous engagement not only helps in refining the product but also establishes a strong relationship with the customer, turning them into brand advocates. Ultimately, integrating comprehensive after-sales strategies into the business model can significantly enhance a company's position in the competitive corflute sheet market, as evidenced by successful industry leaders.

Industry Data: Cost-Effectiveness of High-Quality Corflute Sheets

When selecting corflute sheets for various applications, understanding the cost-effectiveness of high-quality materials is crucial. Industry data shows that, while premium corflute sheets may come with a higher initial price, they offer significant long-term savings through durability and performance. These sheets are resistant to weathering, moisture, and impact, reducing the frequency of replacements and maintenance costs.

Moreover, the overall value of high-quality corflute sheets extends beyond mere cost savings. Businesses benefit from improved branding opportunities, as these sheets can be customized with vibrant prints and designs that withstand the test of time. This enhances visibility and promotional effectiveness, ultimately leading to a stronger market presence. In a competitive landscape, investing in high-quality corflute sheets can be seen not just as an expense, but as a strategic decision that fosters growth and enhances brand reputation over time.

Comparative Analysis: Manufacturer Reputation vs. Repair Frequency in Corflute Sheets

When selecting a manufacturer for corflute sheets, understanding the relationship between manufacturer reputation and repair frequency is crucial. A reputable manufacturer typically invests in quality control processes, ensuring that their products are less prone to defects and latent failures. This translates into lower repair frequencies, which not only saves time but also decreases overall costs for businesses relying on these materials. Analyzing industry data often reveals a clear correlation: higher reputation correlates with lower instances of product defects.

Tips for ensuring you choose the right manufacturer include conducting thorough research on their track record. Look for customer reviews and case studies that highlight the longevity and durability of their corflute sheets. Additionally, don’t hesitate to ask about their warranty policies; a trustworthy company will stand by its products and provide comprehensive support in case of any issues.

Another important tip is to consider the manufacturer's engagement with their clientele. Companies that prioritize communication and customer service are more likely to listen to feedback and improve their products over time. Regularly checking in with industry insights or reports can also provide valuable information regarding emerging manufacturers who are gaining recognition for their quality.

Selecting the Right Manufacturer for Best Corflute Sheet Based on Industry Insights and Data

| Manufacturer Reputation | Repair Frequency (per 1000 sheets) | Average Lifespan (years) | Customer Satisfaction (% positive) |

|---|---|---|---|

| Excellent | 5 | 10 | 95% |

| Good | 10 | 8 | 88% |

| Fair | 20 | 6 | 75% |

| Poor | 35 | 4 | 60% |