- export5@runpingpp.com

- 24 Hours Online

Industry News

Top 10 Benefits of Pp Corrugated Boxes for Your Packaging Needs

In the ever-evolving landscape of packaging solutions, the significance of choosing the right materials cannot be overstated. Among the various options available, **Pp Corrugated Boxes** have emerged as a favorite due to their versatility and effectiveness. According to packaging industry expert Dr. Emily Chen, "The adaptability and resilience of Pp Corrugated Boxes make them an indispensable choice for modern packaging needs." As businesses strive to meet customer demands while optimizing costs, understanding the benefits of these innovative boxes is crucial.

Pp Corrugated Boxes stand out for their lightweight yet sturdy construction, offering a reliable solution for transporting and storing goods. Their design not only protects products during transit but also aligns with eco-friendly practices, as they can be recycled and reused. The advantages of utilizing Pp Corrugated Boxes extend beyond mere protection; they facilitate better branding and presentation, enhancing the overall customer experience. By exploring the top ten benefits of incorporating Pp Corrugated Boxes into packaging strategies, businesses can unlock new levels of efficiency and sustainability in their operations.

Understanding PP Corrugated Boxes and Their Composition

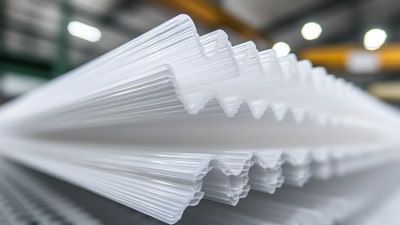

PP corrugated boxes are an innovative packaging solution made from polypropylene, a thermoplastic polymer known for its durability and flexibility. The structure of these boxes typically consists of a fluted polypropylene core sandwiched between two flat walls, providing impressive strength while remaining lightweight. This unique design not only enhances their resistance to moisture and chemicals but also allows for greater ease of handling and transport, making them ideal for a variety of industries.

The composition of PP corrugated boxes also contributes significantly to their eco-friendliness. Unlike traditional cardboard, these boxes can be recycled and reused multiple times, reducing waste in landfills. They are also resistant to tearing and crushing, which minimizes the risk of product damage during transit. Additionally, their vibrant colors and the ability to print high-quality graphics directly on the surface can enhance brand visibility. Overall, PP corrugated boxes are an effective solution for businesses looking to optimize their packaging while maintaining sustainability and cost-effectiveness.

Durability and Strength: Key Advantages of PP Corrugated Boxes

PP corrugated boxes have gained significant traction in the packaging industry, primarily due to their exceptional durability and strength. Unlike traditional packaging materials, PP corrugated boxes are engineered with a unique structure that enhances impact resistance and structural integrity. A study by Smithers Pira indicates that the global demand for such lightweight yet strong packaging solutions is projected to increase by approximately 8% annually, reflecting the industry's shift towards more sustainable and resilient materials. This growing preference for PP corrugated boxes stems from their ability to withstand rough handling and environmental stressors without compromising the integrity of the enclosed products.

Furthermore, the strength of PP corrugated boxes is evident in their remarkable load-bearing capacity, making them ideal for various applications—from food packaging to electronics. These boxes can endure varying weights and pressures, significantly decreasing the likelihood of product damage during transit. According to recent industry reports, PP corrugated boxes can withstand loads exceeding 350 lbs without deformation. This reliability not only protects the merchandise but also enhances customer satisfaction by ensuring that products arrive in pristine condition. As businesses increasingly prioritize durability in their packaging solutions, the advantages of PP corrugated boxes continue to solidify their role as a preferred choice in the marketplace.

Top 10 Benefits of PP Corrugated Boxes for Your Packaging Needs

Lightweight Nature of PP Corrugated Boxes for Shipping Efficiency

The lightweight nature of PP corrugated boxes significantly enhances shipping efficiency, making them a popular choice across various industries. Unlike traditional cardboard, PP corrugated boxes weigh considerably less without compromising strength and durability. This reduction in weight can lead to lower shipping costs, as carriers often charge based on the total weight of the shipment. It also allows businesses to pack more products in a single shipment, optimizing freight space and reducing the number of trips required for transport.

Additionally, the lightweight design of PP corrugated boxes facilitates easier handling and maneuverability during logistics operations. Workers can easily lift and transport these boxes without the risk of injury or fatigue, which can be common with heavier materials. Moreover, the inherent strength of PP corrugated material ensures that even lightweight packaging can withstand the rigors of transportation, offering excellent protection for the contents inside. This balance of lightweight construction and robust performance makes PP corrugated boxes an ideal solution for businesses looking to streamline their shipping processes while maintaining product safety.

Environmental Benefits of Using PP Corrugated Boxes in Packaging

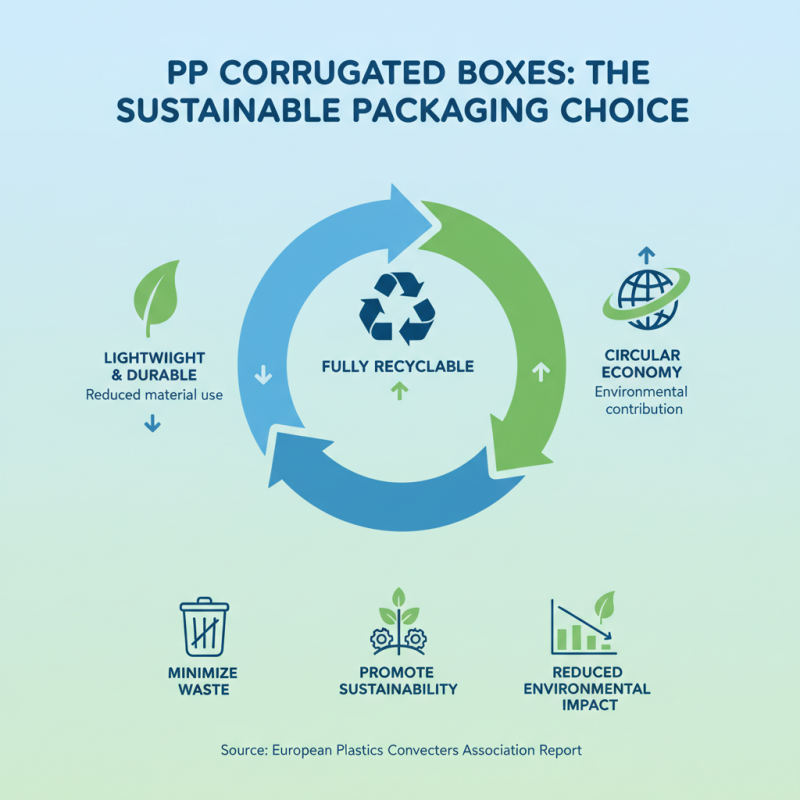

The use of PP corrugated boxes is becoming increasingly popular in the packaging industry, largely due to their environmental benefits. According to a report by the European Plastics Converters Association, polypropylene (PP) is not only lightweight and durable but also fully recyclable. This feature significantly reduces the environmental impact compared to traditional packaging materials such as cardboard and PVC. As a result, companies that adopt PP corrugated boxes can contribute to a circular economy, minimizing waste and promoting sustainability.

Moreover, PP corrugated boxes produce fewer greenhouse gas emissions during their life cycle. A study conducted by the Plastic Waste Management Institute revealed that switching from traditional materials to PP alternatives can lead to a reduction of up to 50% in CO2 emissions. This is critical as businesses face increasing pressure to meet sustainability goals and reduce their carbon footprints. By choosing PP corrugated boxes, companies can lessen their environmental impact while maintaining high standards of packaging protection and efficiency.

Cost-Effectiveness of PP Corrugated Boxes for Businesses and Consumers

PP corrugated boxes are increasingly recognized for their cost-effectiveness, serving as an ideal packaging solution for both businesses and consumers. According to industry reports, the lightweight nature of PP corrugated boxes can lead to significant savings on shipping costs, which accounts for a large portion of logistics expenses. In fact, studies indicate that switching to PP corrugated packaging can reduce overall shipping costs by up to 15%, making it a financially prudent choice for enterprises looking to optimize their supply chains.

Furthermore, these boxes demonstrate impressive durability and versatility, which enhances their value proposition. They are resistant to moisture, chemicals, and impact, allowing for a wider range of applications without compromising integrity. This durability translates into less waste and lower replacement costs, contributing to long-term savings. Businesses can also benefit from the recyclability of PP materials, appealing to environmentally conscious consumers and potentially boosting brand loyalty.

Tips: When evaluating packaging solutions, consider the total cost of ownership, which includes initial purchase price, shipping expenses, and potential disposal costs. Additionally, assess the specific needs of your products; for items that require extra protection, PP corrugated boxes are a robust option. Lastly, don't overlook the importance of design; investing in tailored sizes can further enhance efficiency and reduce material waste, optimizing your packaging strategy.

Top 10 Benefits of PP Corrugated Boxes for Your Packaging Needs

| Benefit | Description | Cost-Effectiveness |

|---|---|---|

| Lightweight | PP corrugated boxes are much lighter than traditional cardboard boxes. | Reduced shipping costs due to lower weight. |

| Durability | They are resistant to moisture and have excellent strength properties. | Longer lifespan than traditional packaging materials, reducing replacement costs. |

| Recyclability | Made from 100% recyclable materials. | Lower environmental impact can lead to tax incentives for businesses. |

| Versatility | Suitable for various products, including food and electronics. | Reduced need for multiple packaging solutions. |

| Customizability | Can be easily customized in size and design. | Improves brand recognition without significant extra costs. |

| Safety | Non-toxic and safe for food contact. | Avoids costs related to food safety recalls. |

| Impact Resistance | Design offers good protection against impacts. | Reduces damage claims during transit. |

| Cost-Effective Production | Manufacturing is efficient and economical. | Lower production costs lead to savings for consumers and businesses. |

| Long-Term Use | Can be reused multiple times. | Cost savings over time through reuse. |

| Aesthetic Appeal | Available in various colors and finishes. | Enhances product presentation and sales potential. |

Related Posts

-

Exploring the Future of Pp Corrugated Boxes at China Import and Export Fair 2025: Trends and Opportunities

-

Exploring the Impact of Pp Corrugated Sheet Innovations at the 138th Canton Fair 2025 in China

-

What is Pp Corrugated Box and Why It Dominates the Packaging Industry Trends

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

Advantages of Using Best Corrugated Plastic Rolls for Your Business Needs

-

Unlocking Quality: Your Guide to Sourcing the Best Plastic Corrugated Sheets from Reliable Suppliers