- export5@runpingpp.com

- 24 Hours Online

Industry News

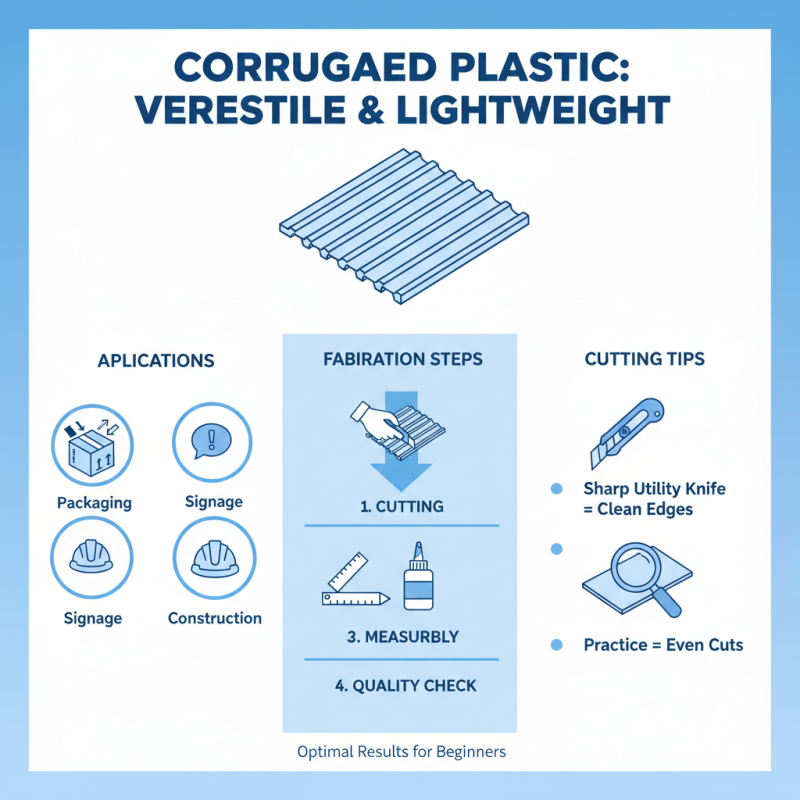

How to Use Corrugated Plastic for Versatile Applications?

Corrugated plastic is a remarkable material, known for its versatility. Industry expert Dr. Emily Chen once stated, "Corrugated plastic opens doors to countless applications." This speaks to its wide-ranging uses in various fields.

From signage to packaging, corrugated plastic has become essential. Its lightweight nature makes it easy to transport and install. Many people overlook its potential in creative projects. Yet, it can also be underappreciated in terms of sustainability.

However, challenges exist. The production process of corrugated plastic can generate waste. Many are still unaware of recycling options. As we explore its applications, we should reflect on both its benefits and environmental impact. Embracing innovation while considering responsibility is crucial.

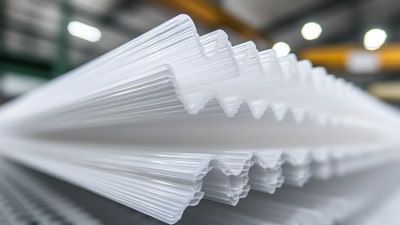

Understanding Corrugated Plastic: Composition and Properties

Corrugated plastic, often known as twin-wall plastic, is made from durable polyethylene. This lightweight material consists of two flat layers with a ribbed structure in between. A report by Smithers Pira shows that the global corrugated plastic market is expected to reach $20 billion by 2027. This statistic reflects its growing popularity and versatility. The ribbed structure allows for increased strength while keeping the weight low.

One of the key properties of corrugated plastic is its resistance to moisture and chemicals. This makes it ideal for various applications, such as signage, packaging, and construction. In fact, in tests conducted by the American Society for Testing and Materials (ASTM), corrugated plastic demonstrated superior impact resistance compared to traditional materials. However, it does have some limitations. Prolonged exposure to UV light can degrade its structural integrity over time.

The ability to print on corrugated plastic also opens opportunities for customization. Colors can be vibrant and designs unique. However, not all inks adhere well to this surface. This inconsistency can lead to subpar results. Users must carefully select the right printing methods to ensure durability. Overall, corrugated plastic offers potential benefits, but caution is required in its applications.

Common Applications of Corrugated Plastic in Various Industries

Corrugated plastic is gaining popularity in various industries for its remarkable versatility. This lightweight material, often referred to as twin-wall plastic, has a range of practical uses. It is widely used in signage, packaging, and construction. Outdoor signs made from corrugated plastic are weather-resistant and durable. This makes them ideal for temporary and long-term displays.

In the packaging industry, corrugated plastic is used for making durable boxes. These boxes can protect items during shipping. Additionally, they are reusable, making them an eco-friendly option. In construction, this material serves as temporary barriers for safety. These barriers are lightweight and easy to transport. Yet, they provide decent protection on job sites.

Tips: When using corrugated plastic, consider its thickness. Thicker sheets offer better durability but may be heavier to handle. Proper cutting tools can ensure clean edges. Additionally, avoid exposing it too long to direct sunlight, as it can weaken over time. Remember that while it’s sturdy, it’s not invincible; regular checks for wear can extend its lifespan. For long-term projects, re-evaluate its condition frequently.

Common Applications of Corrugated Plastic in Various Industries

Step-by-Step Guide to Fabricating Corrugated Plastic Products

Corrugated plastic is a lightweight material used in various applications. Its versatility is evident in sectors like packaging, signage, and construction. When fabricating products from corrugated plastic, certain steps are crucial for achieving optimal results. Cutting is often the first step. A sharp utility knife can help create clean edges. However, beginners may struggle with uneven cuts. Practice is necessary.

Next comes assembly. Adhesives or fasteners are used to join pieces. Selecting the right type is essential. Some adhesives may weaken under stress. A professional report from the Plastic Industry Association shows that improper bonding can reduce product lifespan by up to 30%. Consider testing various methods to find the best fit.

Once the product is assembled, finishing touches matter. Simple tasks like smoothing rough edges enhance appearance. Color options also play a role. Bright colors can attract attention, but fading can occur over time. According to market insights, nearly 45% of users noted color deterioration in outdoor applications. It's important to explore weather-resistant options if longevity is desired. Adjustments and refinements are part of the process, reflecting a commitment to quality.

Tips for Maintaining and Cleaning Corrugated Plastic Materials

Maintaining and cleaning corrugated plastic materials can seem daunting. However, regular care can extend their longevity and performance. According to industry reports, properly maintained corrugated plastic can last up to 10 years, making it a reliable choice for various applications.

To clean corrugated plastic, use mild soap and water. Avoid harsh chemicals that can damage the surface. A soft brush can help with embedded dirt. Always rinse thoroughly to prevent soap residue from forming. Just a few minutes of care every month can vastly improve the material's appearance.

Inspecting for damages is essential. Even with the best cleaning methods, wear and tear will occur. Small scratches can accumulate, impacting the material's usability. Addressing these issues early can prevent larger problems down the line. Remember, neglect can shorten the life of your corrugated plastic. Regular maintenance not only keeps it looking good but also ensures that it serves its purpose effectively.

How to Use Corrugated Plastic for Versatile Applications? - Tips for Maintaining and Cleaning Corrugated Plastic Materials

| Application | Maintenance Tips | Cleaning Method |

|---|---|---|

| Outdoor Signage | Inspect regularly for fading or damage. | Use mild soap and water; rinse thoroughly. |

| Packaging Material | Store in a cool, dry place to avoid warping. | Wipe with a damp cloth; avoid abrasive cleaners. |

| Craft Projects | Check for cuts or damages before use. | Clean with a soft brush to remove dust particles. |

| Temporary Fencing | Reinforce edges regularly to maintain stability. | Hose down to remove dirt; avoid high pressure. |

| Display Boards | Keep away from direct sunlight to prevent discoloration. | Use a glass cleaner for shiny surfaces. |

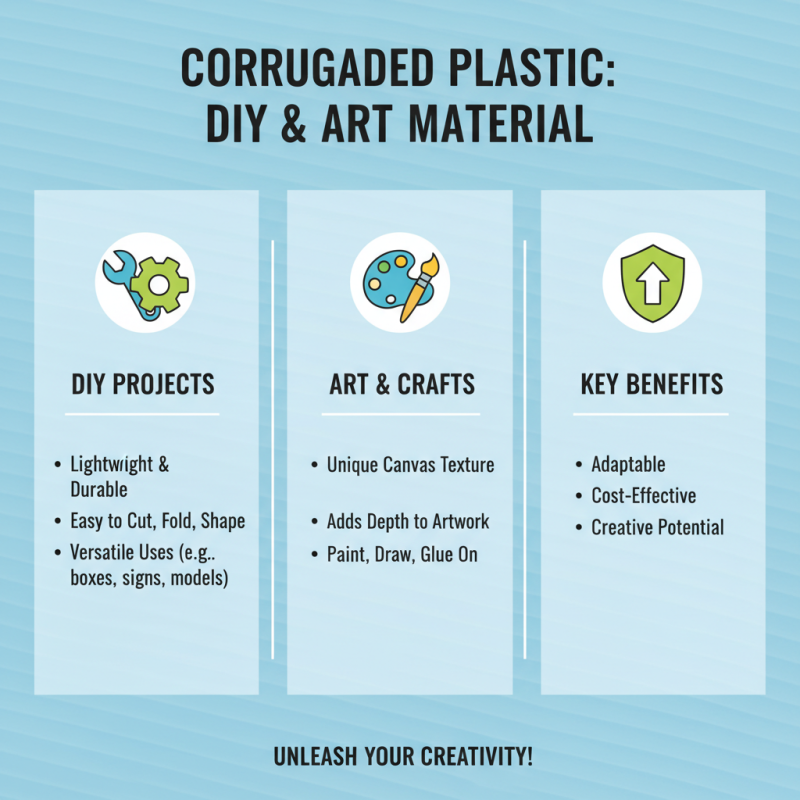

Innovative Uses of Corrugated Plastic in DIY Projects and Art

Corrugated plastic is an amazing material for DIY projects and art. This lightweight yet durable material can adapt to various uses. You can cut, fold, and shape it easily, making it perfect for creative endeavors. For art projects, consider using corrugated plastic as a canvas. The texture adds depth, enhancing your artwork's visual appeal.

Tips: When cutting, use a sharp utility knife for cleaner edges. Be cautious with sharp tools. Also, consider painting or decorating the surface with weather-resistant materials to ensure longevity.

In DIY tasks, corrugated plastic works well for storage solutions. Create bins or organizers to declutter your space. It’s easy to customize sizes to fit your specific needs. Some people struggle to achieve neat finishes. Make sure to plan the measurements before cutting; it saves time and reduces waste.

Experiment with layering pieces for three-dimensional effects in your art. A common mistake is overcomplicating designs. Start simple and build on your ideas. The beauty of corrugated plastic lies in its flexibility. Embrace imperfections; they often lead to unexpected creativity.

Related Posts

-

Unlocking Advantages of Best Corrugated Plastic for Your Business

-

2026 Best Corrugated Plastic Uses and Benefits Explained?

-

Top 10 Manufacturers of White Corrugated Plastic from China at the 137th Canton Fair

-

Exceptional Manufacturing of Best Corrugated Plastic from China Serving the Global Market

-

The Future of Sustainable Solutions with Best White Corrugated Plastic

-

Uncompromising Quality Yellow Corrugated Plastic Crafted in China for Global Success